Sensors

We provide a wide range of sensors, analyzers, and equipment for different manufacturing processes, enabling industries to achieve accurate monitoring, precise control, and consistent product quality. Our offerings include instruments for measuring pressure, temperature, flow, level, moisture, thickness, and chemical composition.

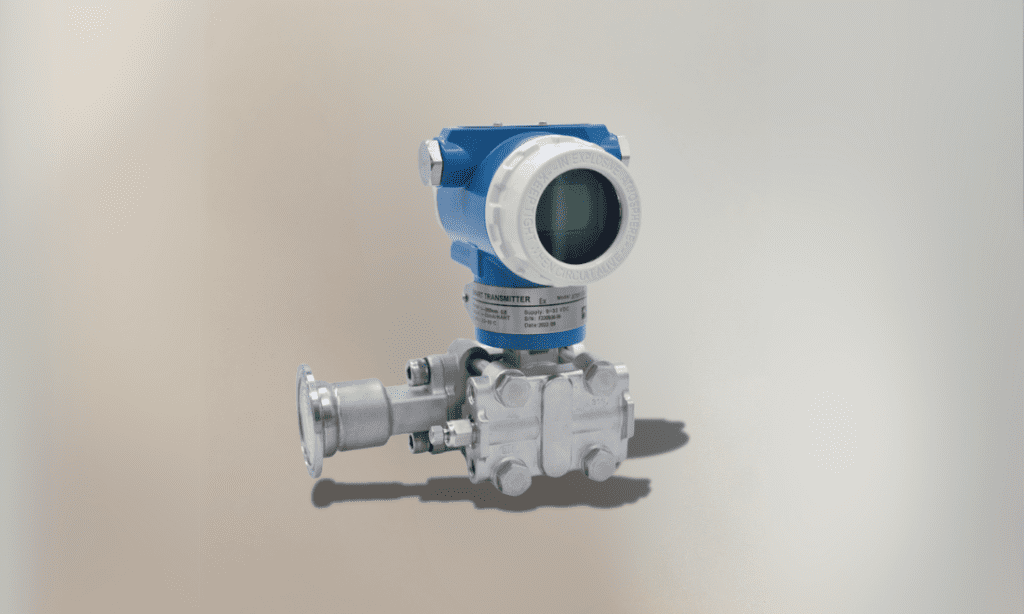

A device that measures the force or “pressure” of a gas or liquid. It detects how much force the fluid is putting on surfaces, like the walls of a pipe or a tank, and converts this information into an electrical signal that can be read and monitored.

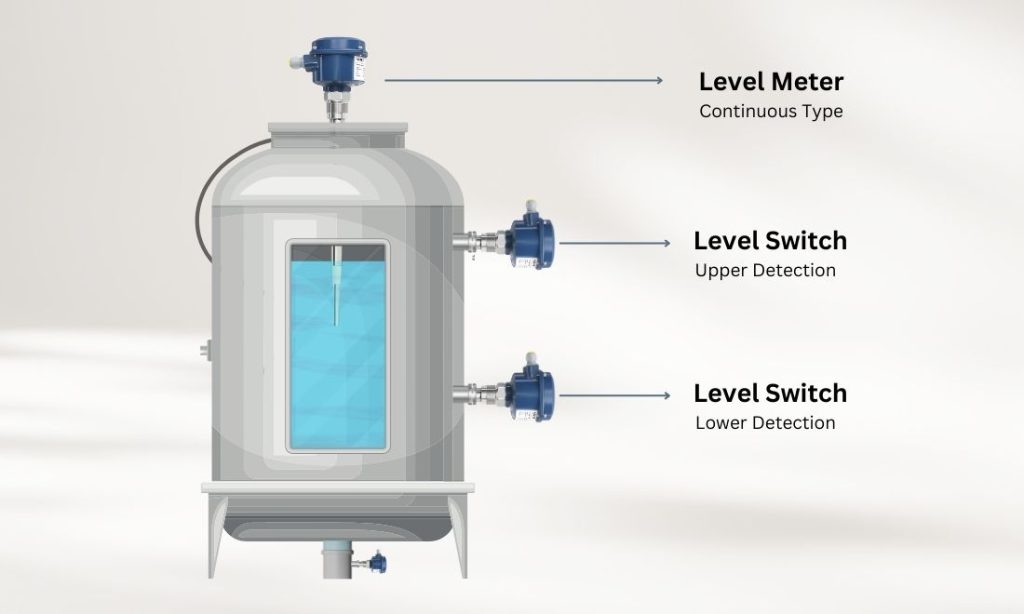

Online level measurement refers to real-time, continuous monitoring of liquid or solid levels within tanks, vessels, or other containers. Unlike manual or intermittent measurements, online level measurement uses advanced sensors to provide constant data on the levels of substances such as chemicals, water, slurries, or bulk solids.

Used to measure how thick or thin an object or material is. It does this by sending a signal, like sound waves or ultrasound, through the material and measuring how long it takes for the signal to bounce back. Helpful in industries where precise measurements are important, such as in manufacturing metal sheets, plastic parts, or glass. They make sure materials meet quality standards and aren’t too thick or too thin for their intended purpose.

Temperature Sensors, Temperature Transmitters

Measures the amount of heat energy or coldness generated by a system, allowing it to detect and monitor temperature changes accurately. It converts thermal energy into readable signals—either analog or digital—that can be interpreted by instruments, controllers, or data loggers.

Online Refractometers

This device continuously measure the concentration of substances dissolved in liquids, like sugars, salts, or chemicals, as part of a production process. They use light to determine how much the liquid bends, or refracts, which indicates its concentration or purity.

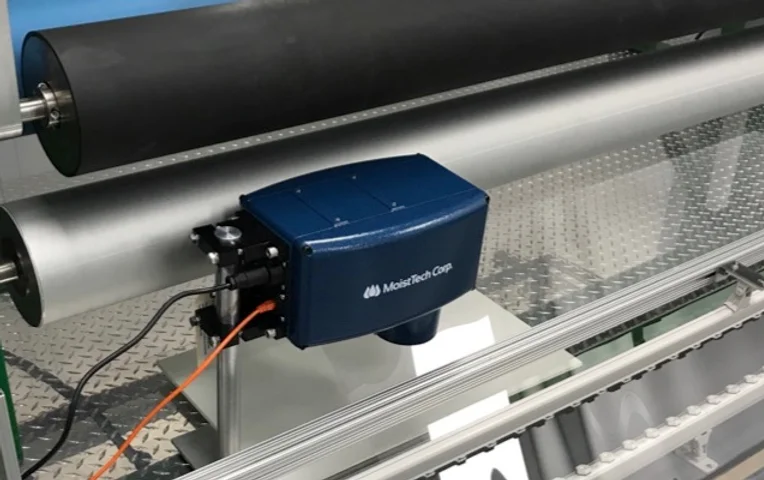

Moisture Sensors

Real-time measurement and monitoring of moisture content in materials during production or processing. This type of moisture measurement is typically done using sensors that continuously analyze moisture levels without the need to stop the production process or manually test samples.

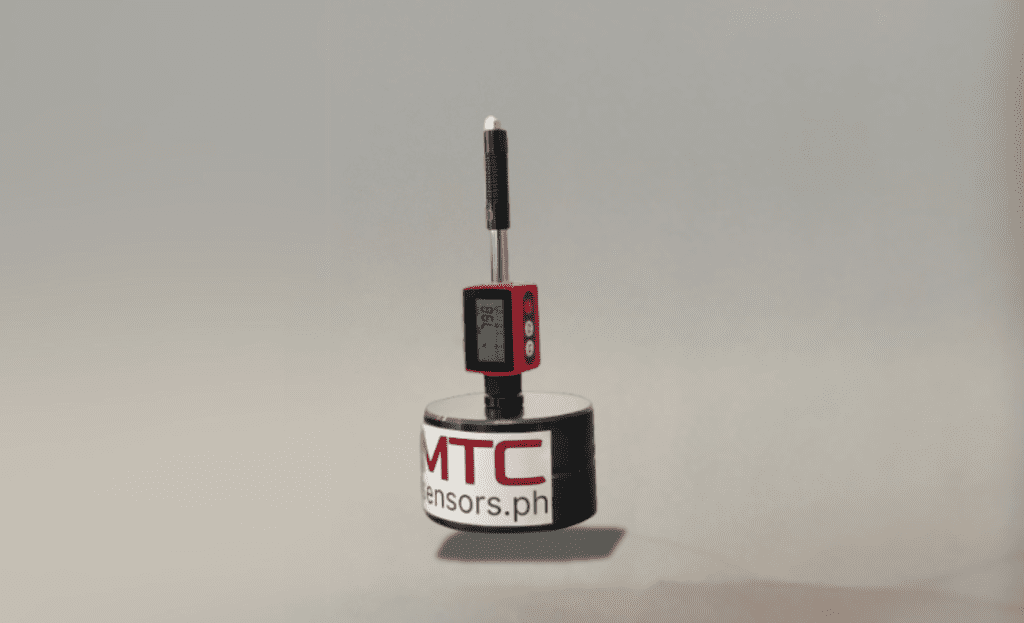

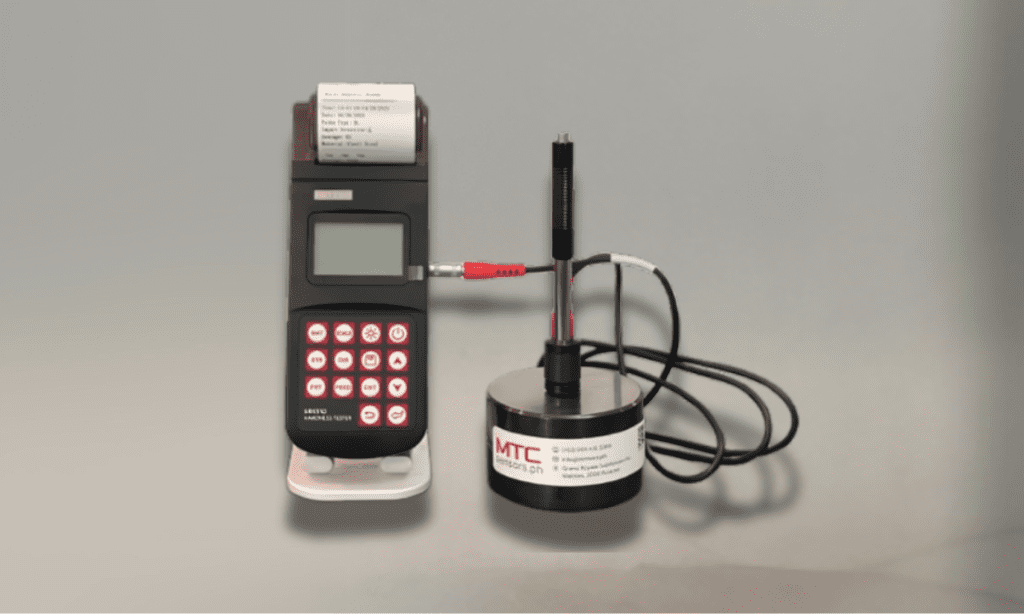

Hardness Sensors

A hardness sensor detects and quantifies how hard a surface or material is by applying a controlled force and measuring the material’s response. This helps determine the mechanical strength and wear resistance of solids—often metals, plastics, coatings, or composites.

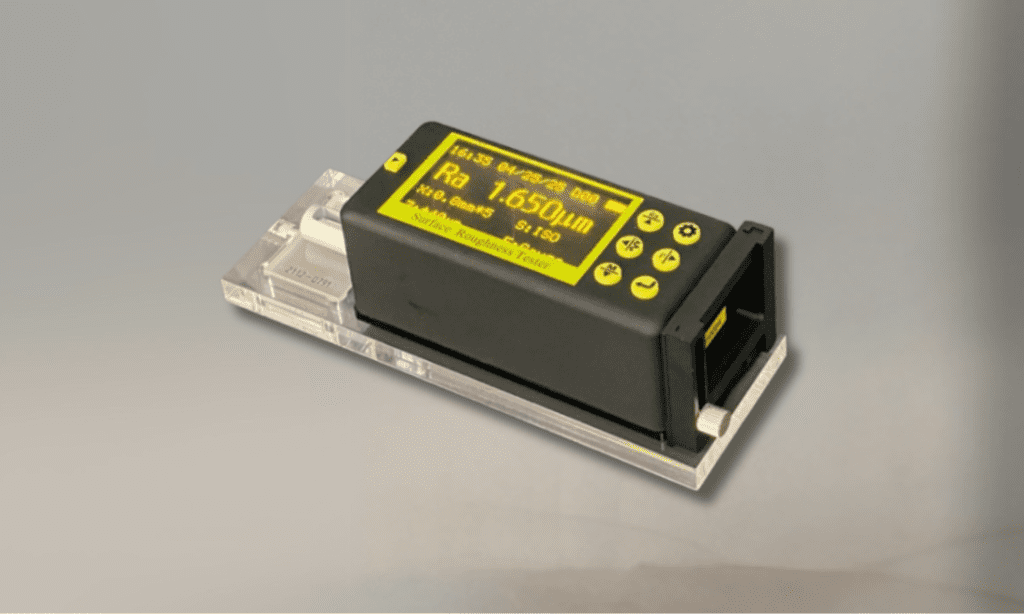

Roughness Sensors

A roughness sensor, also known as a surface roughness meter or roughness tester, is a precision device used to measure the texture or degree of roughness of a surface. These sensors are essential in quality control and surface inspection processes across various manufacturing industries.

RELATED TOPICS

Measure water quality online with specific input parameters such as pH, ORP, Conductivity, Dissolved solids, Metal Contamination of Water and more.

Cement moisture sensors are specialized devices designed to accurately measure the moisture content in cement and related materials during production.

The primary purpose of a tank level sensor is to inform whether a tank is empty or full or to report the fluid amount in the tank.

A pressure sensor is an instrument that senses a mechanical pressure and either displays this pressure, transits this pressure to another location or both.

There is a difference in application between a level switch and a continous level measurement sensor.

Various advanced technologies are available for precise measurement of liquid levels in tanks across industrial and commercial settings.

Contact Measurement Technologies Corporation:

Mobile No:

(+63) 905 431 1969

(+63) 961 889 4213

Email:

info@sensors.ph

Address:

Waling Waling Street, Grand Royale Subdivision Rd, Malolos, 3000 Bulacan

Hours Open:

Monday – Friday

9:00am – 5:00pm

LIST OF OUR PRODUCTS

- 1120 Series Indicators

- 1220 Series Indicating Switches

- 1226X Explosion-Proof Switch

- 1126P-2 Portable Indicator

- Meri-Cal

- Sampling

- Blending

- Analyzing