Types of

Level Switches

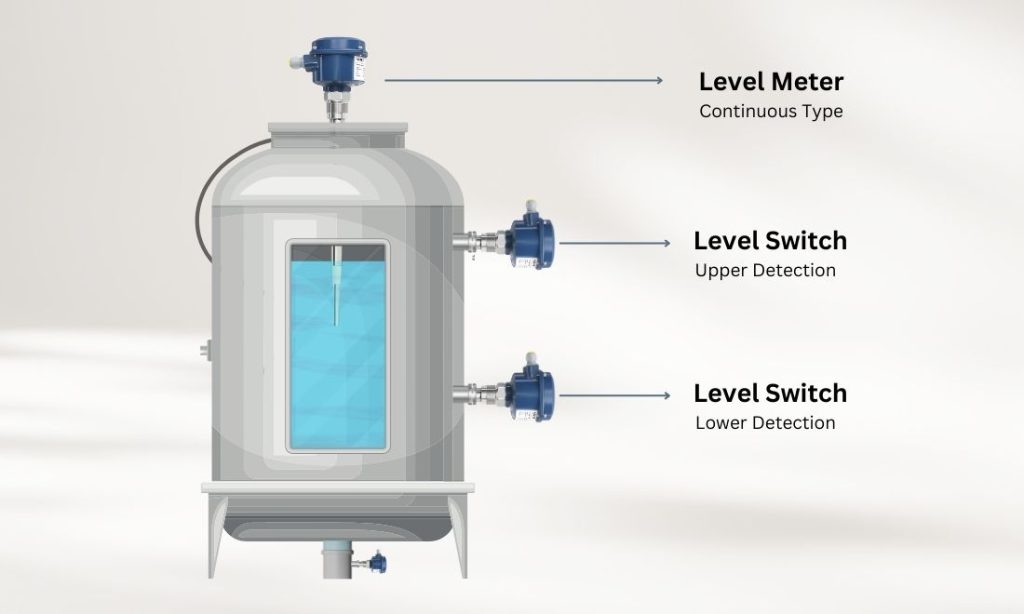

This is a very broad subject but basically there are so many types of level sensor available these days that it is not impossible to cover any kind of application one might encounter. It is important to take a look at a system design to determine what kind of material is being measured and whether or not the contact for the level sensor should be open or closed in an alarm condition.