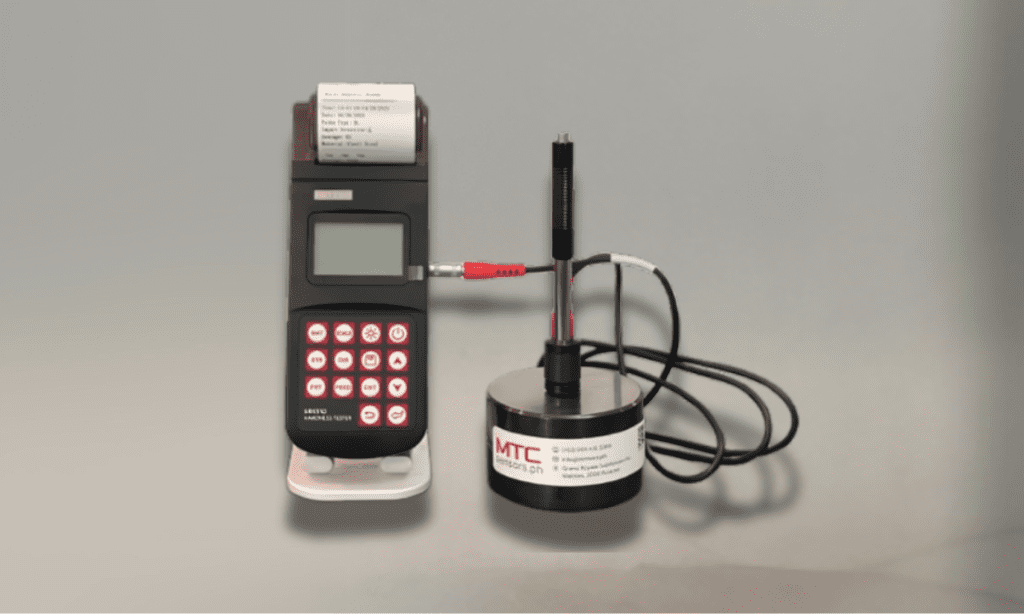

MH310 portable Leeb hardness tester, based on Leeb hardness measuring principle, quick and easy on-site test the hardness of series metal materials, support free conversion between Leeb, Brinell, Rockwell hardness scale and others,It uses high-contrast segment LCD to display clear ,stable performance. integrated high-speed thermal printer ,which can print on-site measurements. It is widely used in annealing, tempering, quenching , quality control for the work piece; hardness testing for machine tool and automobile chassis ; on-site hardness testing of in-service non-removable parts ; quality testing for hardware, forging, machine tools and special steels; quality control for batch production process and so on.Good quality and effective cost ,which is a wise choice for regular need of hardness testing .

Measuring Range: (170~960) HLD

Error and Repeatability:

- Impact device D 760±30HLD, ±6 HLD; 530±40HLD, ±10HLD

- Impact deviceDC 760±30HLDC, ±6HLD; 530±40HLDC, ±10HLDC

- Impact deviceDL 878±30HLDL, ±12HLDL; 736±40HLDL, ±12 HLDL

- Impact deviceD+15 766±30HLD+15, ±12HLD+15; 544±40HLD+15, ±12HLD+15

- Impact deviceG 590±40HLG, ±12HLG; 500±40HLG, ±12HLG

- Impact device C 822±30HLC, ±12HLC; 590±40HLC, ±12 HLC

Impact Direction: Vertically downward, oblique, horizontal, oblique, vertical upward, and automatically identify

Material: Steel and cast steel, cold work tool steel, stainless steel, rey cast iron, nodular cast iron, cast aluminum alloys, BRASS (copper-zinc alloys), BRONZE (copper-aluminum/tin alloys), wrought copper alloys

Hardness Scale: HL、HB、HRB、HRC、HRA、HV、HS

Paper Roll: width (57.5 ± 0.5) mm, diameter: 30mm, long-term imports of paper to ensure long-term data storage

Display: High-contrast Segment LCD

Integrated Data Memory: 100 measurement series. (Relative to average times 32~1)

Battery: 6V (Ni-MH battery pack)

Power Supply: 9V/500mA

Recharge Time: 2.5-3.5hours

Continuous Operating Period: About 150 hours (with default brightness)

Communication: USB1.1

Based on the principle of Leeb hardness testing theory. It can measure many metallic materials.

One main unit can match to6 impact devices

Support Steel, when using D/DC sensor to test steel, it can show HB directly, no need to check manually.

High-contrast Segment LCD, easy to use

Software calibration automatically.

100 groups (impact times 32 ~ 1) hardness measurements, each set of data includes single testing value, average value, measurement date / time, impact direction, frequency, material, hardness, and other information.

Real-time display the remaining battery power, charging progress is displayed while charging.

High brightness EL back-light displayfor easy use in dimly environment.

Automatic sleep and shutdown and other power-saving features

Integrated thermal printer with the instrument as a whole, and quiet operation, fast print speeds, you can print the test report on-site.

Equipped with PC software (optional), with functions of measurements transmission , value storage management, statistical analysis of the measured value, the print report of measured value, batch setting instrument parameters , to meet the higher requirements of quality for activities and management.

Small size, portable, , stable and reliable performance, suitable for harsh environment field operations, prevent from vibration, shock and electromagnetic interference.

Dimension: 212mm×80mm×32mm

- Die cavity of molds

- Bearings and other parts

- Failure analysis of pressure vessel, steam generator and other equipment

- Heavy work piece

- The installed machinery and permanently assembled parts.

- Testing surface of a small hollow space

- Requirements of formal original record for test results

- Material identification in the warehouse of metallic materials

- Rapid testing in large range and multi-measuring areas for large-scale work piece

Measuring Range: (170~960) HLD

Impact direction: Vertically downward, oblique, horizontal, oblique, vertical upward, automatically identify

Error: D, ±6 HLD

Repeatability: D, 6 HLD

Material: Steel and cast steel, cold work tool steel, stainless steel, grey cast iron, nodular cast iron, cast aluminum

Hardness Scale: HL、HB、HRB、HRC、HRA、HV、HS

Impact Energy: D—-11mJ

Impact Weight: D—-5.5g/7.2g

Impact Ball Hardness: D—1600HV

Impact Ball Diameter: D—-3mm

Impact Ball Material: D—-Tungsten Carbide

Sample Surface Roughness: D—-1.6μm;C—-0.4μm

Min Depth of Harness Layer: D≥0.8mm;C≥0.2mm

Display: High-contrast segment LCD

Storage: 100 measurement series (Relative to average times 32~1)

Calibration: Single point calibration

Data Printing: Print the test report

Power Voltage: 6V (Ni-MH battery pack)

Power Supply: 9V/500mA;recharge for 2.5~3.5h

Power Consumption: Lower power design

Standby Period: about 150 hours (with default brightness)

Communication Port: USB1.1

Working Language: English

Shell Material: ABS engineering plastic

Dimension: 212mm×80mm×32mm

Total Weight: 5.5KG

PC Software: Yes

Working Principle

The energy quotient is quoted in the hardness unit HL and is calculated from comparing the impact and rebound velocities of the impact body. It rebounds faster from harder samples than from softer ones, resulting in a greater energy quotient which is defined as 1000×Vr/ Vi.

HL=1000×Vr/ Vi

Where:

HL— Leeb hardness value

Vr — Rebound velocity of the impact body

Vi — Impact velocity of the impact body

Working Conditions

Working temperature:– 10℃~+50℃;

Storage temperature:-30℃~+60℃

Relative humidity: ≤90%;

The surrounding environment should avoid of vibration, strong magnetic field, corrosive medium and heavy dust.