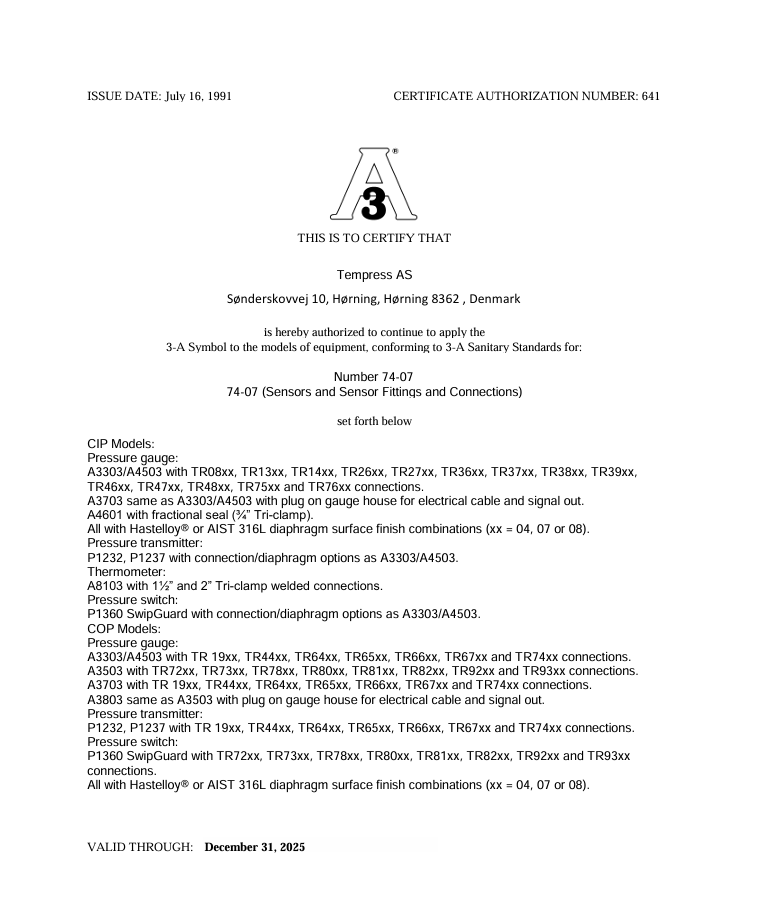

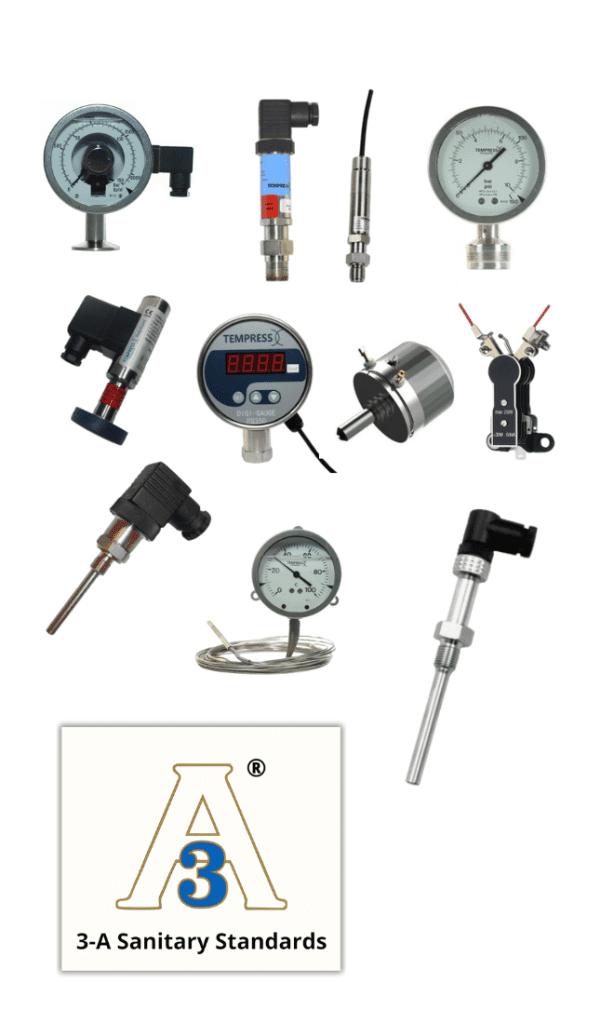

We supply a full range of 3A sanitary instruments designed for hygienic food and beverage applications. Built with stainless steel, polished surfaces, and crevice-free designs, these instruments meet strict 3A hygiene standards and are easy to clean during CIP and SIP processes.

Ex-Stock & Fast Delivery!

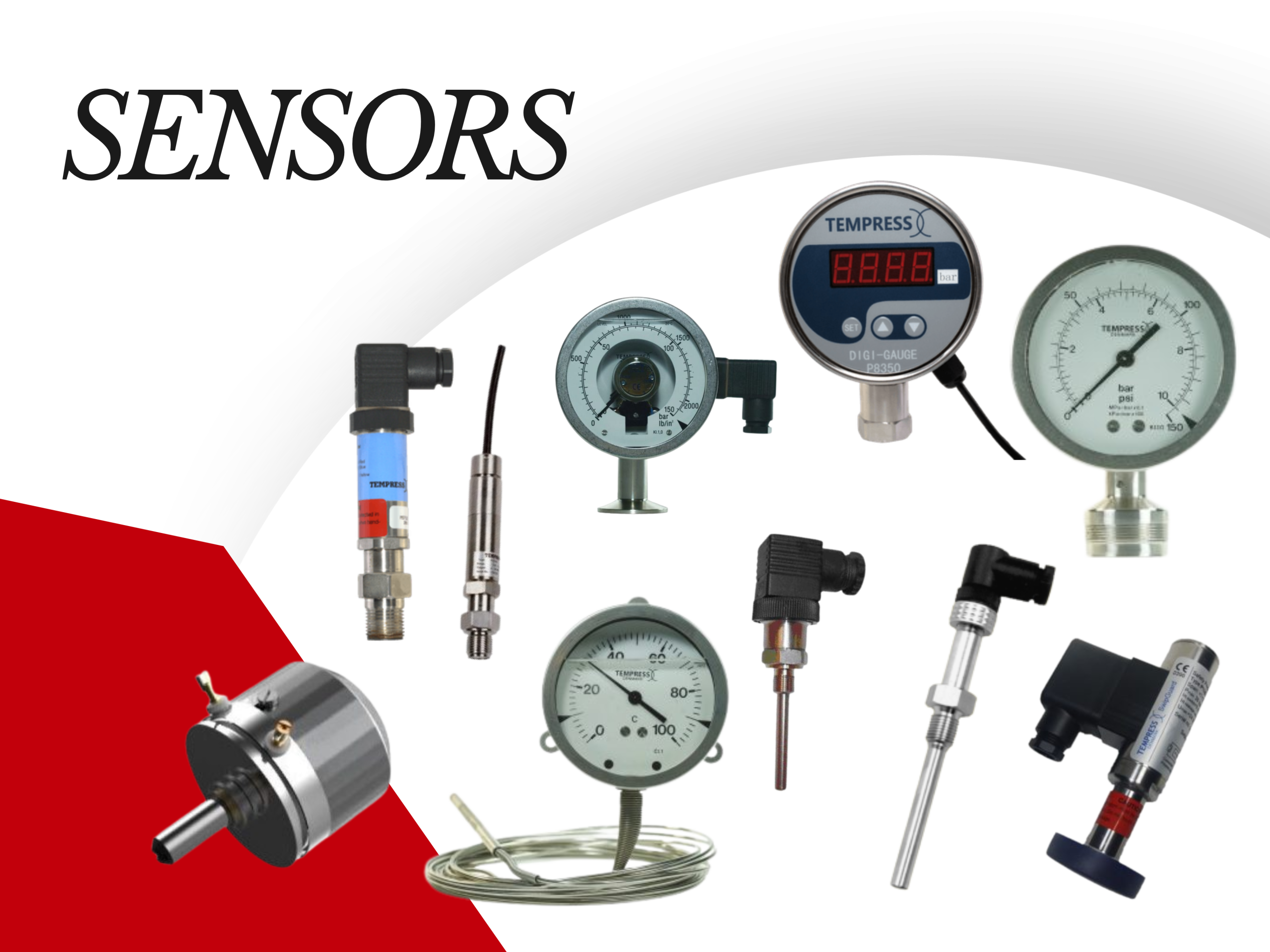

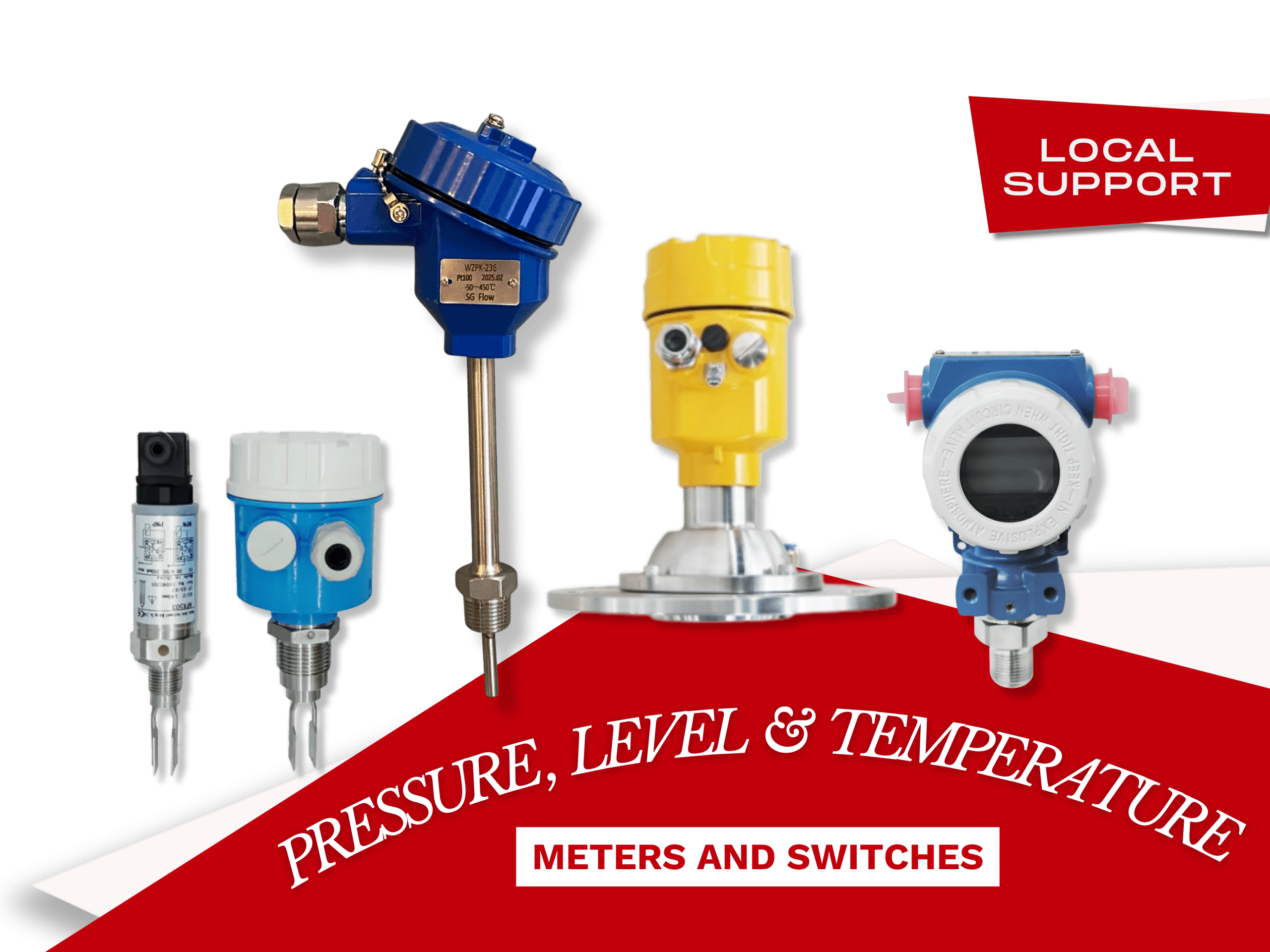

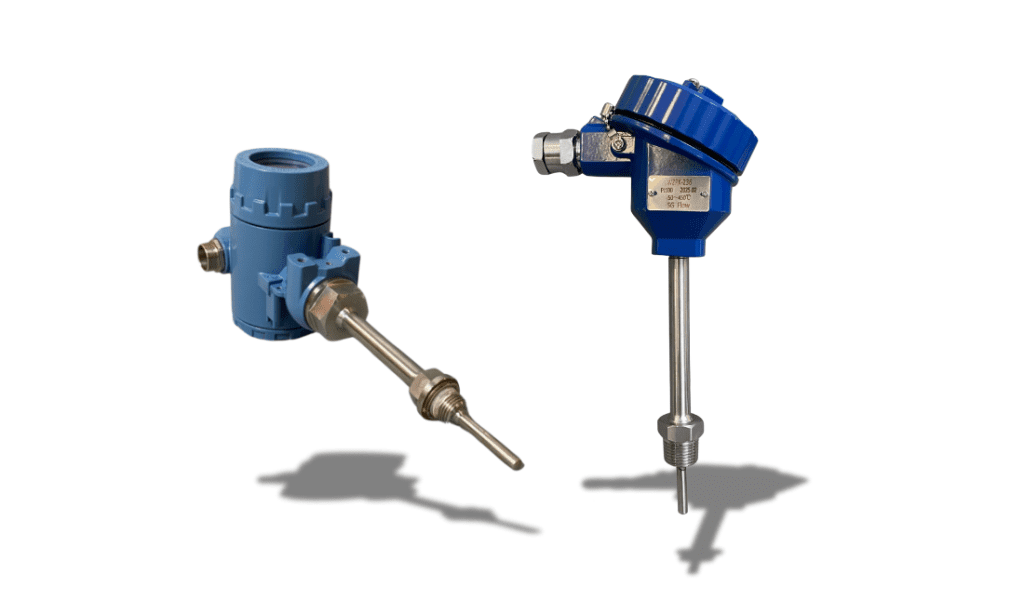

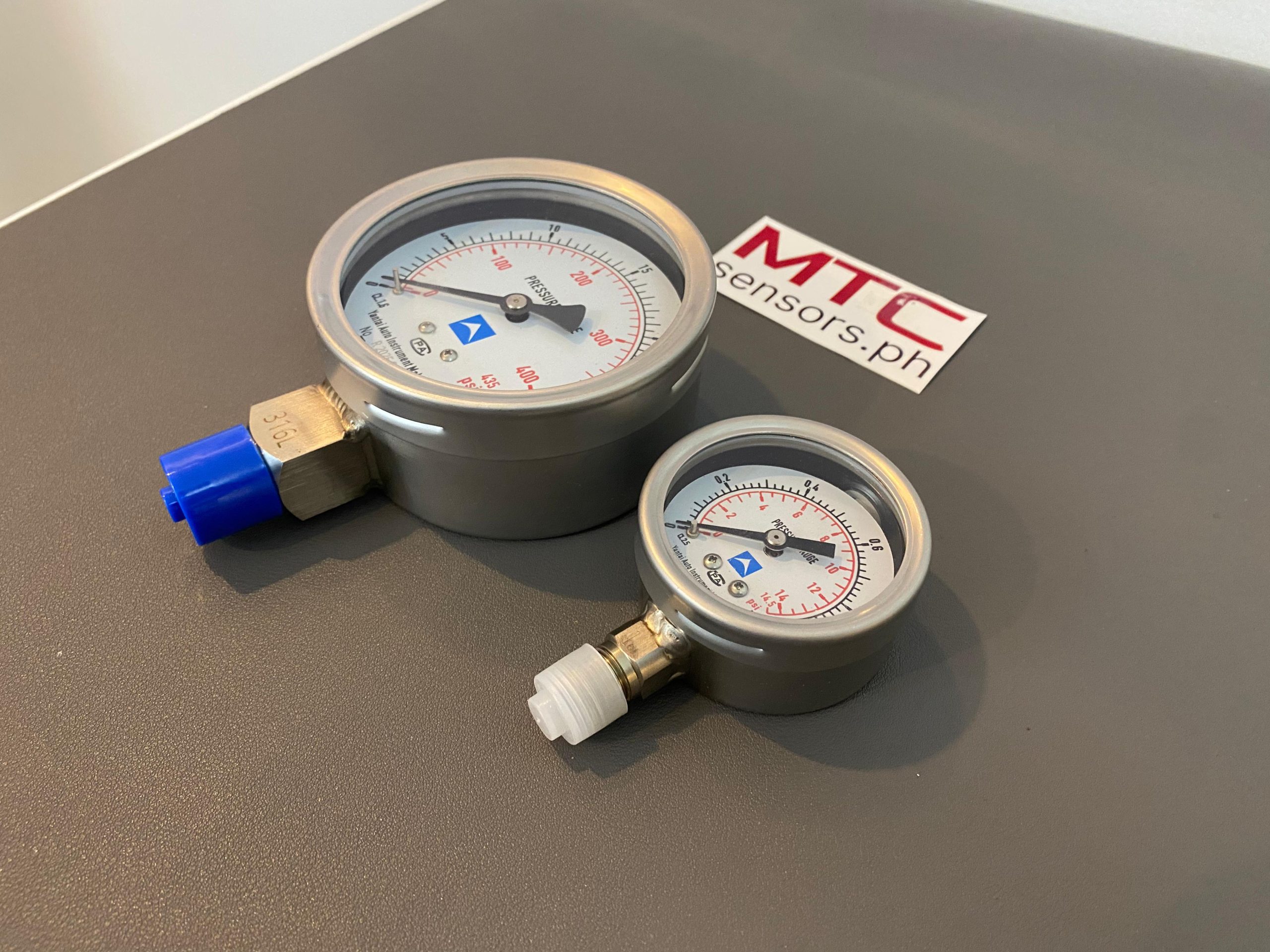

Wide Range of Pressure Transmitters and Pressure Gauges

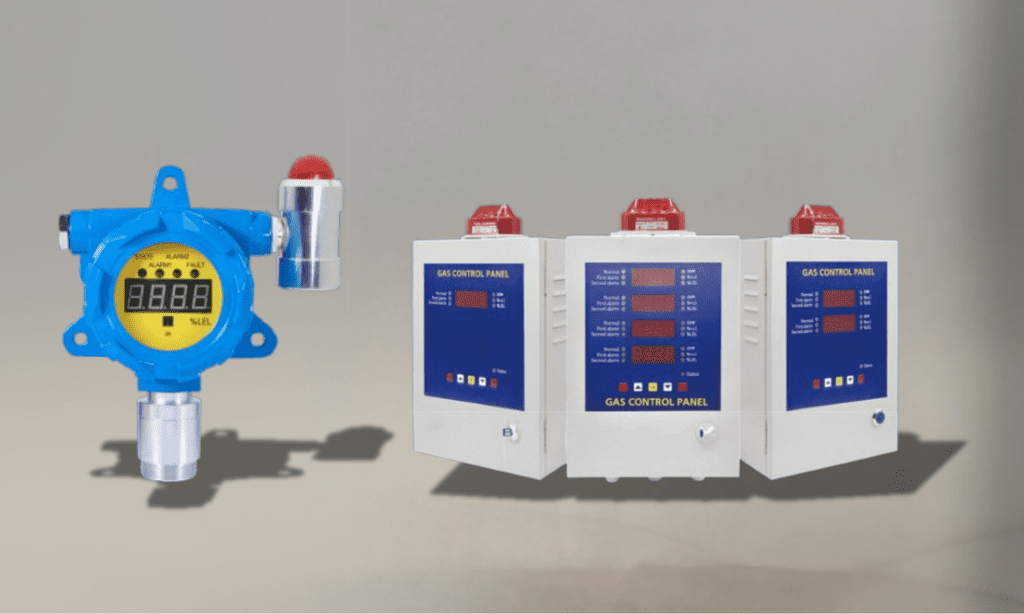

We offer an extensive selection of pressure gages and pressure transmitters from our stock in the Philippines, catering to various industrial and commercial applications. Our products are designed to provide accurate and reliable pressure measurements, ensuring optimal performance and safety in your operations. If the pressure sensors are not in our stock, you can buy them on a fast delivery basis.