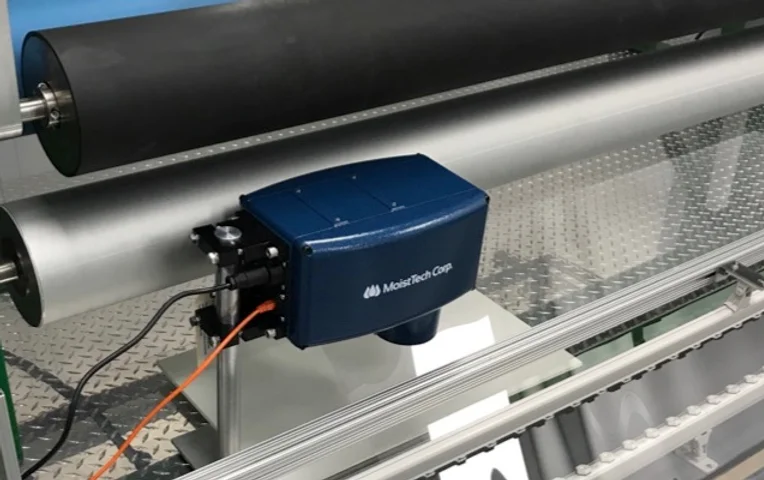

Explosion Proof Enclosure

The MoistTech Explosion Proof Enclosure provides all of the key benefits of our near-infrared with the protection of explosion- proof certified conduits, unions, elbows and nipples to allow the user to make all the external power and communication connections into and from the enclosure as well as fully protect the sensor in any application. MoistTech’s explosion proof enclosure provides the sensors optical bench mounted within a hinged cover enclosure and views through the explosion-proof cover window, mounted using the 4 feet on the bottom of the housing. All of the electrical connections are made through an internal terminal strip and top of the line seals prevent environmental egress to the unit.

Why?

MoistTech’s NIR sensor is insensitive to material variations such as particle size, material height & color, our moisture sensors provide continuous, reliable readings with zero maintenance and a one-time calibration with a non-drift optical design allowing operational personnel to confidently make immediate process adjustments based on real-time measurements.

Top of the Line Equipment – MoistTech’s explosion proof enclosure is designed to protect the sensor’s technology from the harsh manufacturing conditions to allow for precise, accurate, and repeatable moisture measurement data.

Product Quality Monitoring – Allows immediate production line adjustments to improve product quality and consistency

Process Optimization – Allows 100% monitoring of the production process to reduce product that is out of specification

Fuel & Energy Consumption Savings – Reducing energy usage in the drying process can be controlled through moisture measurement, resulting in a reduction in energy consumption

Dust Prevention – Measuring moisture content will also assist in the reduction of dust, which directly decreases the risks of explosions

Moisture range: 0 – 0.1%, 0 – 99%, ppm range subject to application

Measured constituents: up to 3 in one sensor

Accuracy: 0.1% – subject to application

Repeatability: 0.01%

Calibration codes: store up to 50 standard codes

Operating temperature: 0-200f (93c)

Optical measurement distance: 4-8 in (10-20 cm)

Sampling size: approx. 1.5 in (3.7 cm) diameter on sample

Dimensions: 19.25″x15″x8.25″

Weight: 110 lbs

Enclosure: class 1,2,3 div 1&2, groups b,c,d,e,f,g, zones 1&2, type 3,4,4x

Power: 80-260 vac (50/60 hz), optional 24vdc