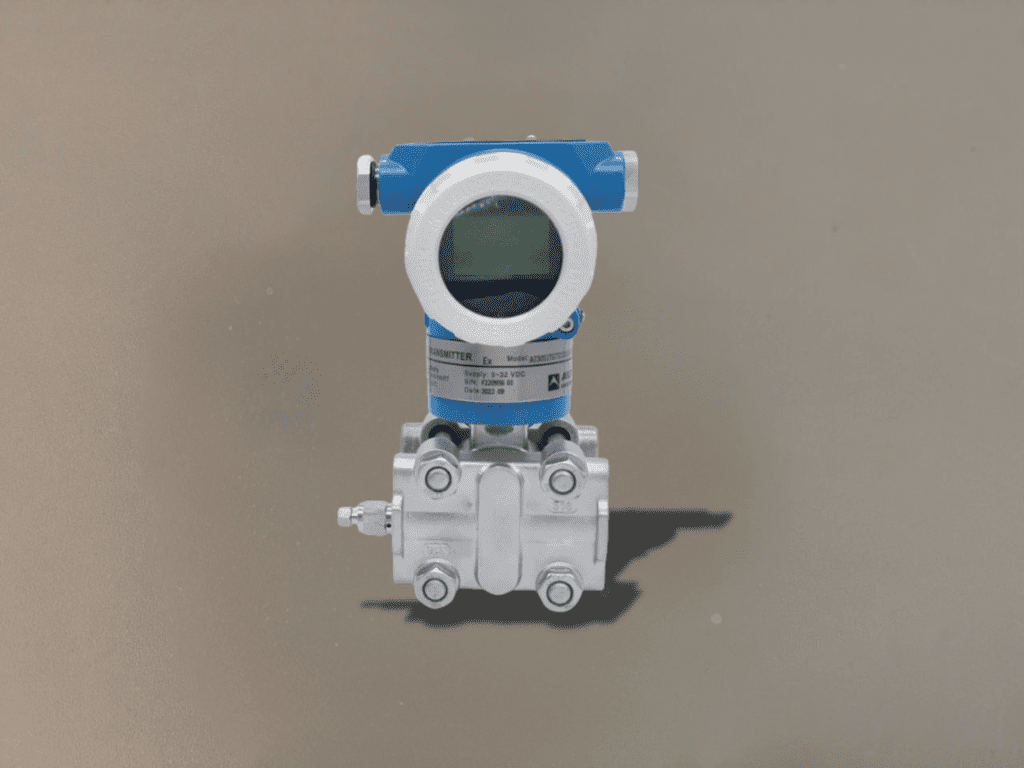

A Differential Pressure Transmitter (or differential pressure sensor) measures the pressure difference between two points in a system. Unlike a standard pressure transmitter that senses pressure from a single port, a differential pressure transmitter features two pressure ports — a high-pressure (positive) side and a low-pressure (negative) side.

The transmitter detects the difference between these two inputs and converts it into a standard electrical output signal, typically 4–20 mA.

In normal operation, the positive pressure side should have a higher pressure than the negative side, allowing the device to accurately measure the differential pressure (ΔP) across a filter, orifice plate, or other process component.

- Process Fluid: Liquid, gas, or steam flow as well as liquid level, density and pressure

- Measuring range: 200Pa-10MPa

- Working Temperature: -25 to +95C

- Current Output: 4 – 20 mA 2 wires Hart Protocol

- Power Supply: 24VDC

- Ambient Temperature: -25 to +120C

- Process connections: 1/4 – 18 NPT or 1/2 – 14 NPT

- Electrical Connections: 1/2”NPT or M20*1.5

- Enclosure:IP65

- Intrinsically Safe: ia II C T6

- Explosion proof: d II B T5

- Diaphragm material: SUS316L, Hastelloy C

- Process control system

- Petroleum industry

- Chemical industry

Process Fluid: Liquid, Gas, Vapor

Diaphragm material: SUS316L, Hastelloy C

Current Output: 4 – 20 mA 2 wires Hart Protocol

Power Supply: 24VDC

Process connections: 1/4 – 18 NPT or 1/2 – 14 NPT

How a Differential Pressure Transmitter Works

Unlike a standard pressure transmitter, which measures pressure from a single port, a differential pressure transmitter has two pressure ports — a high-pressure (HP) side and a low-pressure (LP) side. The device senses the difference between these two pressures and converts it into a standard electrical output signal, typically 4–20 mA, 0–10 V, or a digital output such as HART or Modbus.

Under normal conditions, the positive (high-pressure) side has a higher pressure than the negative (low-pressure) side, and the resulting pressure differential is used to monitor or control process performance.

Many models also include advanced features such as:

- Square root extraction, useful for flow measurement (since flow rate is proportional to the square root of ΔP)

- Digital communication protocols for integration with control systems.

- Local display options for on-site reading and calibration

Why Differential Pressure Measurement Matters

Monitoring differential pressure helps operators:

- Detect changes in process efficiency

- Identify equipment wear or blockages early

- Maintain product quality and process safety

- Optimize energy use and system performance

Because many industrial processes depend on stable pressure conditions, differential pressure transmitters provide an essential layer of protection and process insight.