Inline blending is a controlled method that allows for the continuous mixing of various blend components to achieve a defined specification. Compared to batch blending, inline blending offers numerous benefits:

- Reduced Process Time: Streamline your operations and get faster results.

- Flexibility: Easily accommodate last-minute changes in shipping schedules.

- Improved Accuracy: Achieve more precise blending specifications.

- Cost Efficiency: Reduce the need for extensive storage capacity and capital investment.

Applications

Crude Oils

Fuel Oils

Bunker Fuel

Ethanol Products

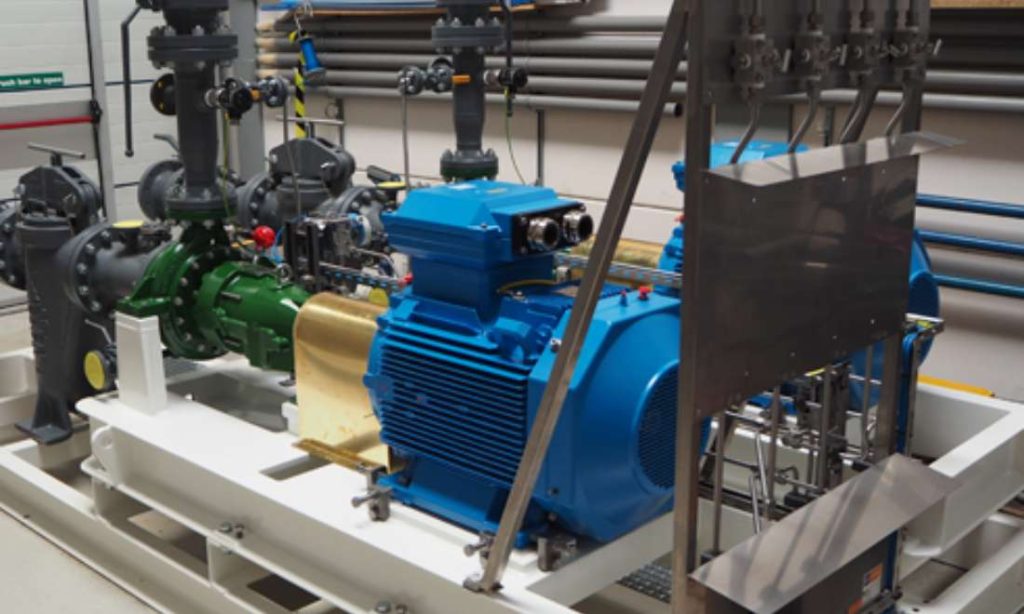

Performance Guarantee

With inline blending it’s not just the purchase of the right components; it is the integration of them to form a complete system. Depending upon the compositions of the liquids, the proper materials need to be selected. The valves, meters, analyzers, etc. enables the blend components to be simultaneously measured and controlled while heading towards the blender header to produce a final product. At the end of the blender header adequate mixing takes place that can be analyzed to allow for a quality trim and blender optimization. The KPS blending solutions are custom designs, supplied as a turnkey package, fully skid- mounted and with an overall performance guarantee.

The selection of the proper blender control philosophy is dependent upon the constraints of the existing infrastructure, the quality of feedstock, and the final product specifications. The control system defines the stability and performance of the blender, and often requires a quality trim function that utilizes online analyzers to continuously optimize the performance of the blender.

By using a combination of measured parameters (such as viscosity, density, sulfur and octane) and/or calculated flow-weighted quality parameters, quality trim blenders can automatically correct for any variations in the feedstock quality or errors arising from the blending models.

The blender philosophy can be migrated directly into the plant wide DCS control system to allow for a completely integrated solution for the plant that is fully supported by operation’s house contractor. Functionalities like recipe management, alarms, reports and batch information can be used up to its full potential and can customize their user interface to meet the requirement.

Choosing the right instrument isn’t just about specs and features—it’s about finding a solution that fits your unique process, enhances productivity, ensures safety, and meets compliance. A careful, criteria-based selection process will lead to better performance, fewer breakdowns, and long-term success for your operation.

Need help selecting the right instrument for your industry?

Reach out to our technical team for expert guidance customized to your process needs.