A tuning fork level switch is a type of point level sensor that uses the principle of vibration to detect the level of a substance, typically liquids or solids. This threaded level switch is suitable for mounting on pipes or tanks, a level switch with a sanitary connection that is cost-effective for industries like the food industry.

For point level detection, tuning fork level switches are a popular option because they provide a dependable and adaptable level measuring solution for a wide variety of industries.

- Industrial Process

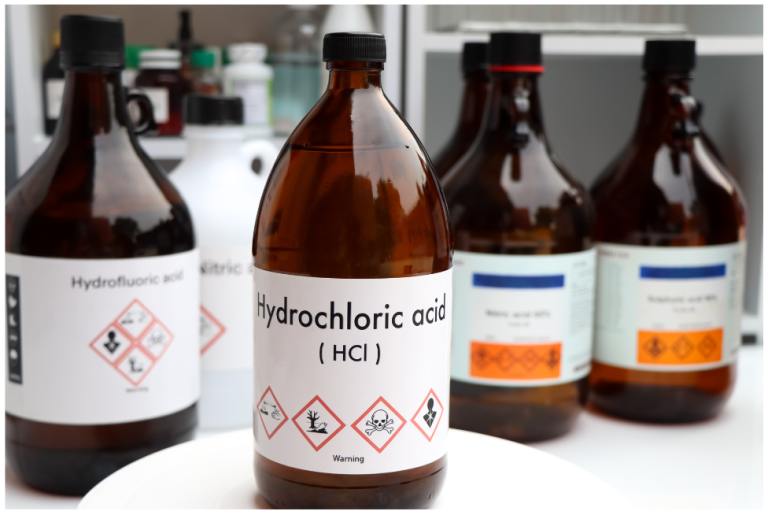

- Chemical Industry

- Pharmaceutical Industry

- Food and Beverages Industry

- Operation is truly affected by free flow, turbulence, bubbles foam, vibration, solids content, coating, liquid properties and product variations.

- Hygienic connectors.

- No calibration is needed, and minimal installation is required.

- Polarity is insensitive and short-circuit protected.

- Adopt industry standard plug/socket connectors.

- No moving parts or gasps, maintenance free.

- Compact design makes the form factor small and lightweight.

- “Quick drop” tuning fork design has a replacement response time for viscous liquids.

Working Principle

The tuning fork vibrates at a resonant frequency through a pair of piezoelectric crystals attached to its base. When the fork of the liquid level switch is in contact with medium, the frequency and amplitude of the tuning fork will change. These changes of the liquid level switch of the tuning fork will be detected and processed by an intelligent circuit and converted into a switch signal.

When the tuning fork is submerged in the substance, the vibration is dampened, causing a change in frequency. This change in frequency is detected by the sensor’s electronics, which triggers a switch to indicate the presence or absence of the substance at a specific level.

Common Applications

Industrial Processes: Monitoring levels in tanks, silos, and hoppers.

Chemical Industry: Detecting levels in reactors and storage tanks.

Pharmaceutical Industry: Monitoring levels in mixing tanks and storage vessels.

Food and Beverages Industry: monitoring of liquid levels in storage tanks, fermentation vessels, and processing tanks.