Liquid Tank Level Measurement

Be informed with the most recent developments, articles and news about our Liquid Tank Level Measurement.

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

Understanding Liquid Tank Level Measurement

Refers to the process of determining the height or volume of liquid inside a tank. This measurement is critical for monitoring, controlling, and managing the storage of various liquids—such as water, chemicals, fuel, oil, and beverages—in industries like manufacturing, agriculture, oil & gas, food processing, and water treatment.

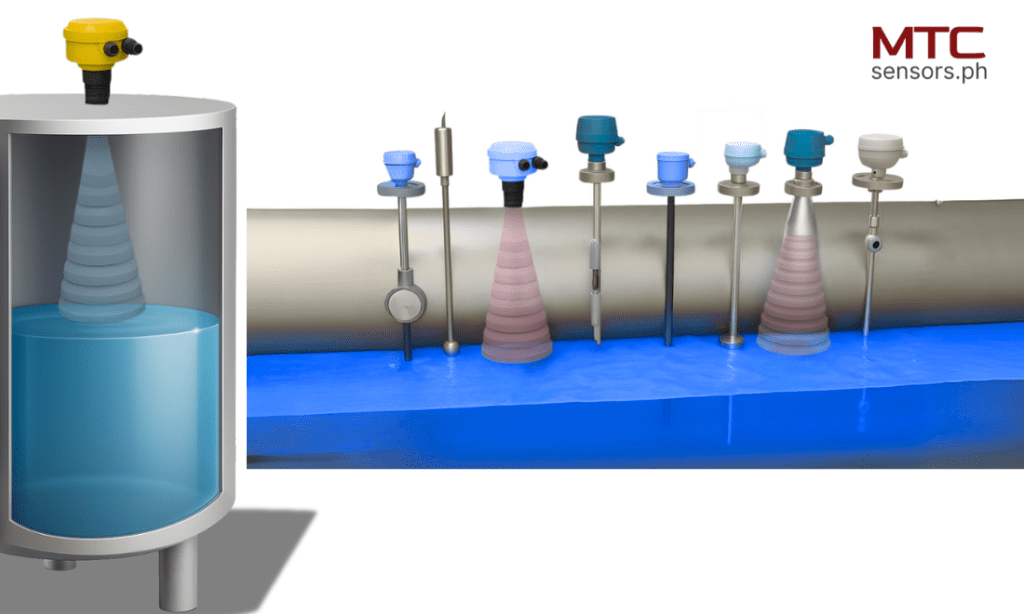

Devices designed for diverse applications vary in shapes and sizes to measure levels. The primary purpose of a tank level sensor is to inform whether a tank is empty or full or to report the fluid amount in the tank. Commonly known as level sensors, transmitters, or gauges, these devices measure point level, resembling a level switch or continuous level instruments that provide operators with the exact fluid amount in a container or tank.

How Do Level Sensors Work?

Level sensors detect the level of materials by measuring various physical properties such as pressure, ultrasonic waves, capacitance, or conductivity. The data collected is then translated into electrical signals and sent to a display or control system for further processing.

Some sensors work continuously, providing real-time level data, while others are point-level devices that only trigger when the level reaches a specific height.

Why It Matters

Accurate level measurement helps:

- Prevent overflows and dry runs

- Ensure efficient inventory management

- Maintain safety and regulatory compliance

Optimize production and process control

Choosing the Right Level Sensor

Selecting the best level sensor depends on several factors:

- Type of material (liquid, solid, foam)

- Tank size and shape

- Environmental conditions (temperature, pressure, dust)

- Required accuracy and response time

Budget and maintenance needs

Consulting with sensor experts or suppliers can help ensure you choose a solution that matches your operational requirements. Contact us if you have any concerns or need assistance. We can recommend the perfect specifications to match your requirements.

Choosing the Right Level Sensor

It’s crucial to understand that level sensors have versatile applications beyond just tank measurements. These sensors are equally effective in open channels and open spaces, providing valuable data across various scenarios. For instance, certain level measurement devices are engineered to measure the distance between two objects, functioning similarly to anti-collision sensors used in industrial settings.

This adaptability makes them ideal for a wide range of applications, including monitoring fluid levels in wastewater treatment plants, open reservoirs, and even in detecting the presence and distance of objects to prevent collisions. By employing these advanced sensors, industries can ensure accurate measurements, enhance safety, and optimize operations in diverse environments.

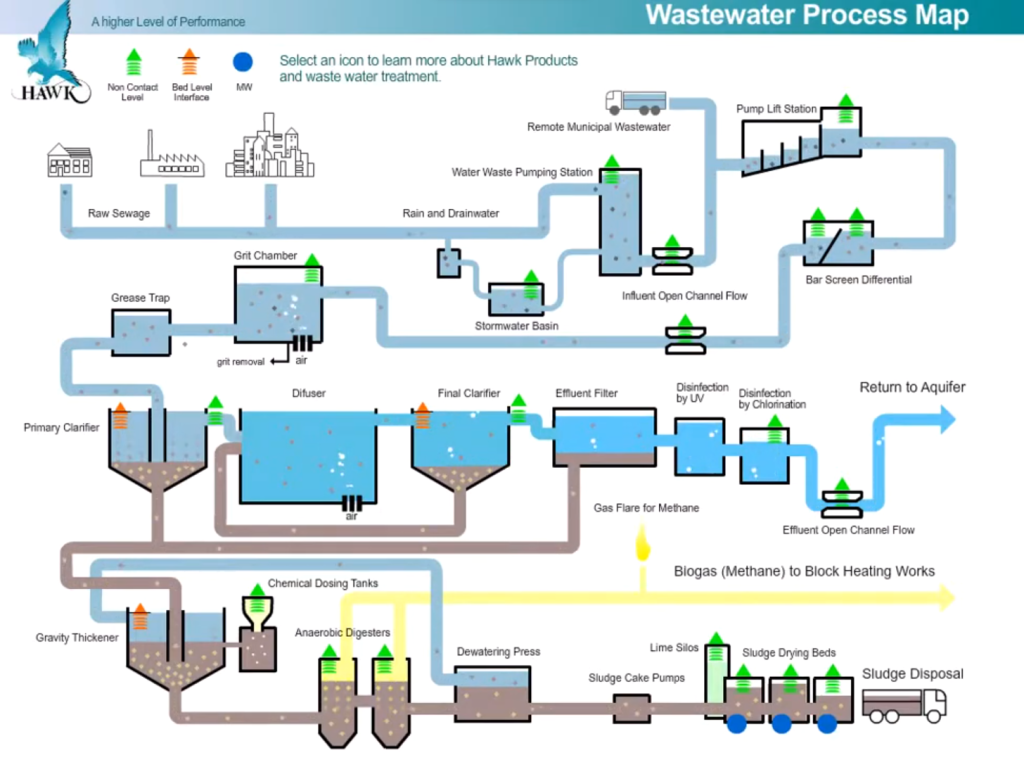

Water Treatment Applications

Level measurement finds numerous applications in water treatment, from raw sewage treatment plants to clarifiers, digesters, dewatering, and sludge separation. It involves liquid levels, including water, water-based liquids, and chemicals in non-pressurized or pressurized tanks. Measuring solids poses challenges, especially when they behave differently from liquids, as solids tend to build up.

Contact vs. Non-Contact Level Sensors

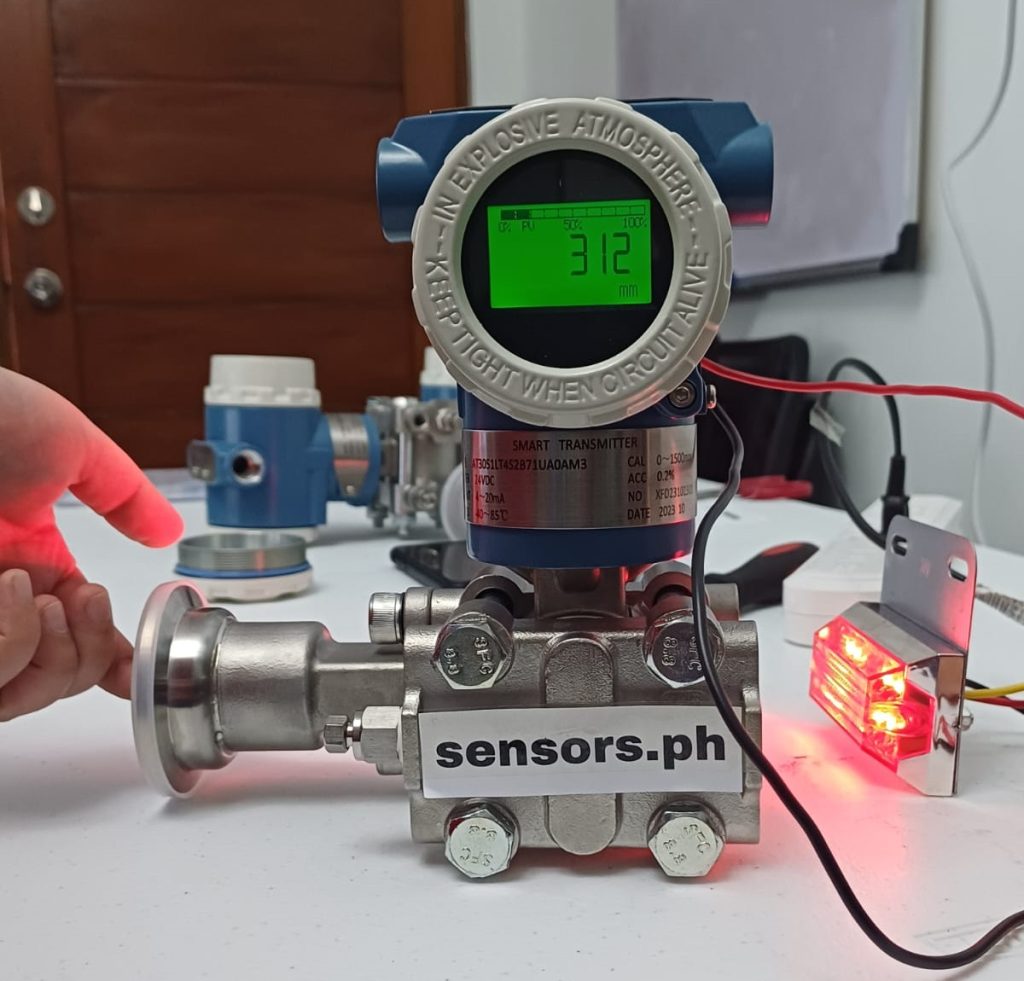

Categorizing level sensors as either contact (intrusive) or non-contact (non-intrusive) depends on the sensor setup. Multiple methods determine fluid levels. A common mechanical level sensor is often referred to as a gauge. Measuring pressure can also indicate levels in a tank or similar application, termed as “Hydrostatic Level Transmitters.”

Testing a pressure-based hydrostatic level sensor in our office involves a stainless steel tank with a mixture of sweetened water for juices. The connections use a Tri-clamp to affix to the adjoining pipe. Calibration of the level transmitter is done by referencing the Water Column.

For point level detection, tuning fork level switches are a popular option because they provide a dependable and adaptable level measuring solution for a wide variety of industries.

Types of Level Sensors

Apart from mechanical sensors, other technologies exploit frequencies across the electromagnetic spectrum. Examples include capacitance level, optics (laser and infrared sensing), conductivity, vibrating fork-type level switches, magnetic float switch, microwave level sensors, radar gauges, and acoustic level technology. Collaborating with Hawk Measurement provides access to the best contacts for application-specific assistance.

Having trouble selecting the best instrument for your application?

Here’s a guide to help you choose the right instrument for your industry. You may also reach out to our technical team for expert guidance tailored to your specific process needs.