Thickness Gauge

Instrument used to measure the thickness of materials — such as metals, plastics, coatings, pipes, glass, rubber, and composites — without damaging the object.

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

Thickness Gauge Supplier in Philippines

Available Products:

A measuring instrument used to determine the thickness of a material or coating, usually without damaging the surface being tested. It is a key tool in quality control, manufacturing, and maintenance inspection, ensuring that materials or coatings meet required standards for strength, protection, and performance.

This device uses ultrasonic sound waves to measure the thickness of various materials, including metals, plastics, ceramics, glass, and composites, without causing damage to the object being measured.

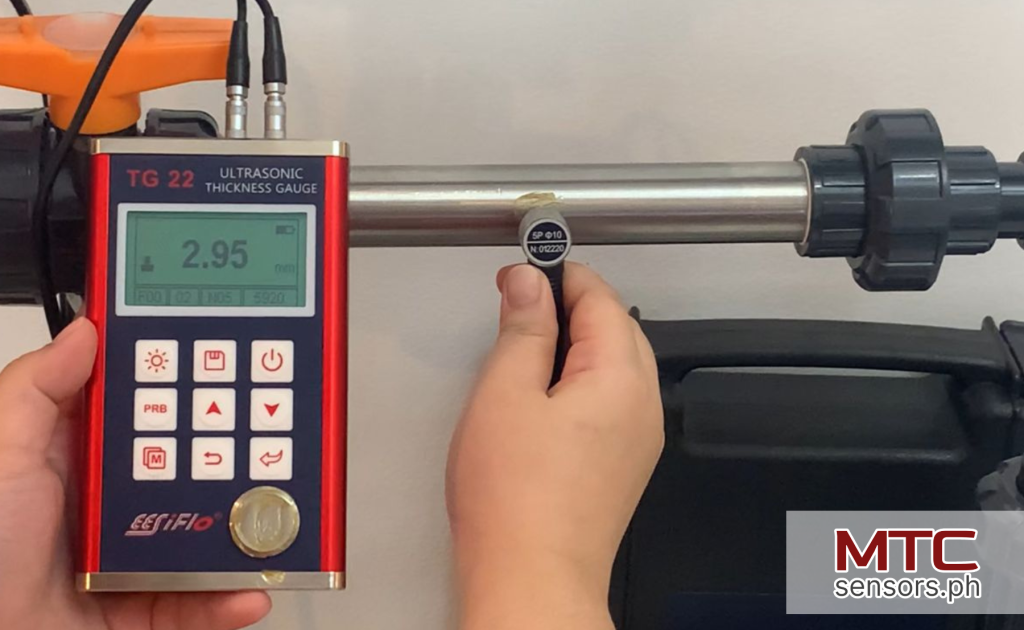

What is an Ultrasonic Thickness Gauge?

An ultrasonic thickness gauge is a precise measuring instrument used to determine the thickness of a material or metal plates from one side.

As a non-destructive testing (NDT) solution, ultrasonic thickness meters are widely used in industries where accurate material thickness is crucial for quality control, safety, and equipment maintenance.

This device uses ultrasonic sound waves to measure the thickness of various materials, including metals, plastics, ceramics, glass, and composites, without causing damage to the object being measured.

Please enquire for alternative solutions when measuring concrete, cement mortar, asphalt bitumen, aggregate rocks and specific sensors for material testing.

Ultrasonic Wall Thickness Gauges go by other names such as wall thickness gauges, portable thickness testers, handheld thickness meters, and thickness sensors. There are several methods to measure the wall thickness of materials such as steel, iron, copper, brass, glass, plastic and more using ultrasonic technology. As long as there is a smooth surface, an ultrasonic measurement can take place on any material that is solid and sonically conductive. Most applications for these thickness devices are too numerous to mention in one page. If the user is unsure if the portable thickness gauge are the solution, then simply get in touch with us to see if we have a model that is able to meet the requirements. Non-destructive equipment is ideal for measuring the effects of corrosion or erosion on tanks, pipes, or any structure where access is limited to one side. Multiple echo options which work through paint will determine the metal thickness of a painted structure without having to remove the coating. Not all thickness gauges are the same, so it is best to make sure that the correct model has been selected so that a user will buy a portable ultrasonic thickness gauge in the Philippines that suits their frequent requirements.

List of Standard Materials in the Thickness Gauge Menu

- Aluminum

- Steel, common

- Steel, stainless

- Brass

- Copper

- Iron

- Nickel

- Cast Iron

- Lead

- Nylon

- Silver

- Gold

- Zinc

- Titanium

The thickness of materials not mentioned in the above list can be programmed into the gauge. The following video shows how to program a thickness gauge to measure an unknown material. Although the EESIFLO video training module is over 10 years old, it is very useful for beginners to understand how to check measurements are correct using Ultrasonic Thickness Gauges.

How is an Ultrasonic Thickness Gauge Sensor Different from a Caliper?

The thickness of materials not mentioned in the above list can be programmed into the gauge. The following video shows how to program a thickness gauge to measure an unknown material. Although the EESIFLO video training module is over 10 years old, it is very useful for beginners to understand how to check measurements are correct using Ultrasonic Thickness Gauges.

Having trouble selecting the best instrument for your application?

Here’s a guide to help you choose the right instrument for your industry. You may also reach out to our technical team for expert guidance tailored to your specific process needs.