Food & Beverage

Common Sensors Used :

Moisture Meters | measure moisture content in grains, powders, and raw materials

Brix Monitors | monitor sugar concentration and liquid consistency

Temperature & Pressure Transmitters | ensure proper cooking, pasteurization, and fermentation conditions

Gas Detectors | detect leaks of CO₂ or other process gases in production areas

_________________________________________________________________________

Proper measurement and control in food processing ensures:

- Consistent product quality and taste

- Compliance with safety and hygiene regulations

- Reduced waste and optimized production efficiency

- Prevention of equipment damage and downtime

Important Features of Sensors Used in the Food & Beverage Industry:

- High Accuracy: Reliable measurements for consistent product quality

- Hygienic Design: Sanitary sensors compatible with food-grade standards (3A, FDA, EHEDG)

- Durable & Reliable: Built for continuous operation in wet, hot, or corrosive environments

- Real-Time Monitoring: Enables fast process adjustments for optimal efficiency

- Flexible Integration: Suitable for pipelines, tanks, conveyors, or packaging lines

Manufacturing & Industrial Automation

Common Sensors Used :

Pressure Transmitters | monitor hydraulic, pneumatic, and process pressures

Oil Meters | measure fluid and gas flow in automated systems

Temperature Sensors & Transmitters | control process temperatures in heating, cooling, and molding applications

Level Sensors | detect material levels in tanks and silos

Vibration and Condition Monitoring Sensors | Electric Motor Checker | track equipment health to prevent mechanical failure

_________________________________________________________________________

Modern manufacturing relies heavily on accurate, real-time data to maintain consistent product quality and safe operations. Our sensors enable:

Important Features of Sensors Used in the Manufacturing & Industrial Automation Industry:

High Precision & Repeatability: Ensures consistent product output

Durable Construction: Suitable for harsh industrial environments

Fast Response Time: Supports high-speed automation processes

Smart Integration: Compatible with digital and analog control systems

Energy-Efficient Design: Reduces operational costs and downtime

Oil, Gas & Petrochemical

Common Sensors Used :

Fixed Gas Detectors | detect toxic, combustible, or flammable gases in confined or open areas

Pressure Transmitters | monitor pressure in pipelines, tanks, and compressors

Radar Level Gauges | measure liquid and solid levels in storage tanks

Oil Meters | track oil, fuel, and gas flow for production and distribution control

Liquid Density Meters | monitor product quality and composition in refining processes

Temperature Sensors & Transmitters | ensure proper control in heaters, exchangers, and reactors

_________________________________________________________________________

Process accuracy and safety are vital in hazardous environments where a single fault can lead to costly downtime or safety risks. Our sensors enable:

Important Features of Sensors Used in the Oil, Gas & Petrochemical Industry:

Explosion-Proof & Intrinsically Safe: Designed for use in hazardous zones (Ex-certified)

High-Temperature & Pressure Tolerance: Built for demanding process conditions

Corrosion-Resistant Materials: Suitable for harsh chemicals and fuels

Precise & Stable Measurements: Ensures consistent performance and safety

Integration Ready: Compatible with PLC, SCADA, and process control systems

HVAC, Clean Room & Environmental

Common Sensors Used:

Air Particle Counters | measure dust and particulate contamination in clean rooms

Airflow Meters & Velocity Sensors | monitor and optimize ventilation systems

Gas Detectors | detect CO₂, VOCs, and other environmental gases

Pressure Sensors & Differential Pressure Transmitters | maintain proper airflow and pressure differentials in critical areas

_________________________________________________________________________

Environmental sensors are designed to continuously monitor air quality, temperature, humidity, and particulate levels. These parameters are vital for:

Accurate measurements allow timely adjustments and prevent costly contamination or process disruptions.

Important Features of Sensors Used in the HVAC & Environmental Industry:

High Accuracy: Reliable readings for temperature, humidity, airflow, and particulates.

Real-Time Monitoring: Continuous data collection for proactive environmental management.

Durable and Reliable: Designed for long-term operation in controlled or industrial environments.

Flexible Installation: Suitable for ducts, ceilings, walls, or portable use.

Compliance Ready: Helps meet ISO, GMP, and cleanroom standards.

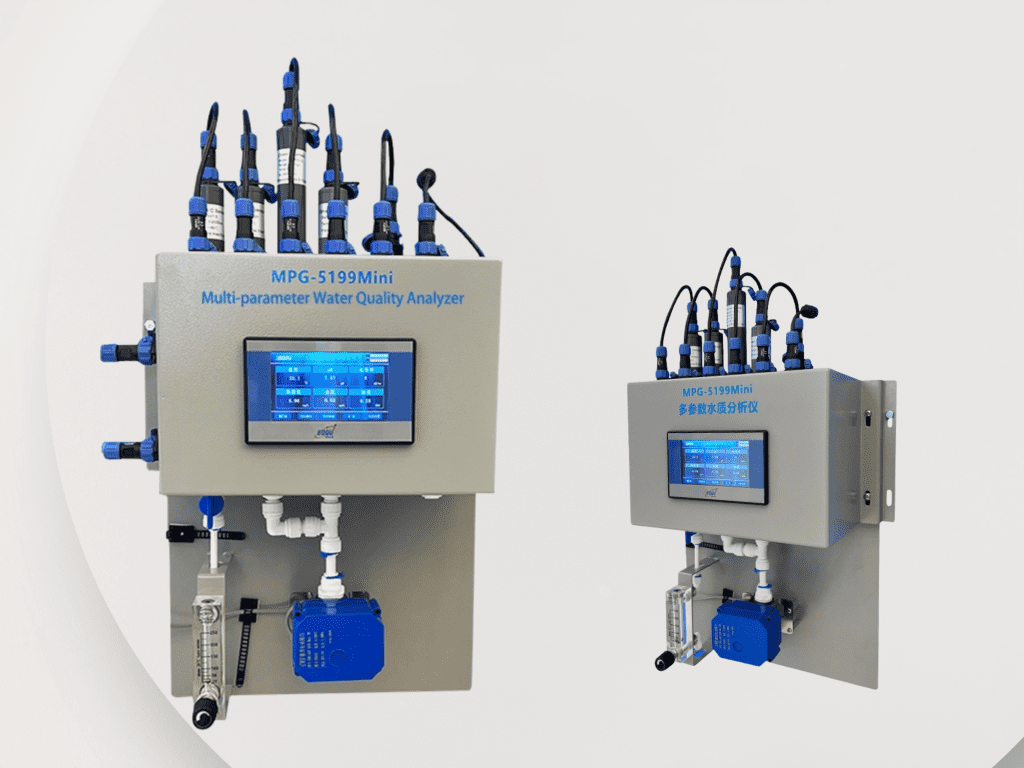

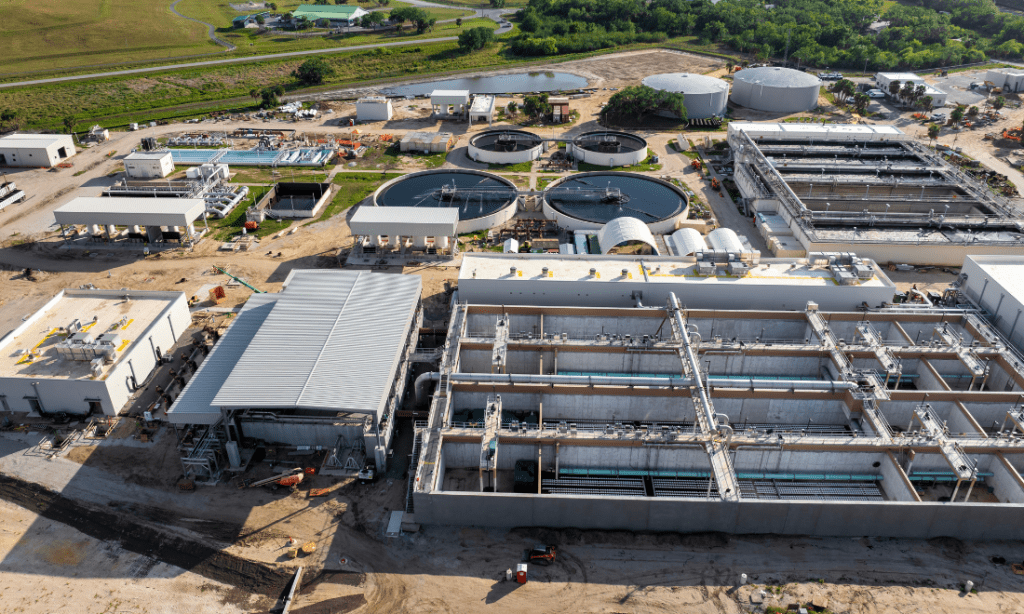

Water & Wastewater Treatment

Common Sensors Used :

pH & ORP Sensors | monitor acidity and oxidation-reduction potential in treatment processes

Level Sensors & Transmitters | maintain proper tank, reservoir, and basin levels

Pressure Transmitters | ensure reliable pumping and pipeline operations

Fixed Gas Detectors | detect toxic or combustible gases in confined treatment areas

_________________________________________________________________________

Effective water and wastewater treatment depends on real-time monitoring of chemical, physical, and flow parameters. Key benefits include:

Important Features of Sensors Used in the Water & Wastewater Industry:

High Accuracy: Reliable readings for pH, ORP, flow, level, and pressure

Durable & Corrosion-Resistant: Built for harsh water, sludge, and chemical environments

Continuous Monitoring: Supports real-time process adjustments

Easy Integration: Compatible with SCADA and PLC systems

Regulatory Compliance: Helps meet local and international water quality standards

Cement & Construction

Common Sensors Used :

Cement Moisture Sensors | monitor moisture in raw materials and finished products

Broken Cement Bag Detectors | detect compromised packaging in production lines

Level Switches & Level Sensors | measure material levels in silos, bins, and hoppers

Pressure & Temperature Transmitters | for kiln, silo, and process monitoring

Dust & Air Particle Monitors | maintain safe air quality and comply with environmental regulations

_________________________________________________________________________

The cement and construction industry operates in dusty, abrasive, and high-temperature environments, where measurement errors can cause production delays or quality issues. Key benefits of using specialized sensors include:

Important Features of Sensors Used in the Cement & Construction Industry:

Durable & Rugged: Built for high-dust, high-vibration, and abrasive environments

High Accuracy: Reliable measurements for process optimization

Easy Installation & Maintenance: Designed for industrial tanks, silos, hoppers, and conveyors

Resistance to Harsh Conditions: Handles high temperatures, humidity, and abrasive dust

Real-Time Monitoring: Enables proactive maintenance and quality control

Pharmaceutical & Chemical

Common Sensors Used :

Pressure Transmitters | ensure consistent vessel and reactor pressure control

Temperature Sensors & Transmitters | maintain precise thermal conditions during reactions and sterilization

pH & Conductivity Sensors | monitor solution purity, concentration, and quality

Oil Meters | measure liquid chemicals and solvents with accuracy

Level Sensors | detect tank levels in reactors, storage tanks, and mixing vessels

Gas Detectors | monitor for toxic or flammable gases in production or storage areas

_________________________________________________________________________

Precision and reliability are key in industries where even the smallest deviation can affect quality or safety. Our sensor solutions are engineered to deliver:

Important Features of Sensors Used in the Pharmaceutical & Chemical Industry:

High Accuracy & Stability: Maintain product quality and batch consistency

Sanitary & Hygienic Design: Available in 3A-certified and clean-in-place (CIP) compatible models

Chemical-Resistant Materials: Suitable for solvents, acids, and corrosive substances

Explosion-Proof & Intrinsically Safe Options: For handling volatile or reactive chemicals

Easy Integration: Compatible with PLC, SCADA, and automation systems

Marine & Power Generation

Common Sensors Used :

Pressure Transmitters | for monitoring fuel, oil, and hydraulic pressures

Temperature Sensors & Transmitters | for engines, turbines, and exhaust systems

Oil & Gas Meters | measure fuel, lubrication oil, and coolant flow

Level Sensors | detect liquid levels in ballast tanks, fuel tanks, and water reservoirs

Vibration Sensors | monitor rotating equipment such as pumps, generators, and motors

Gas Detectors | detect combustible or toxic gases in confined or hazardous areas

_________________________________________________________________________

Whether it’s for monitoring engine performance or ensuring safe energy distribution, sensors play a key role in maintaining continuous and reliable operations. Our solutions help:

Important Features of Sensors Used in the Marine & Power Generation Industry:

High Durability: Built to withstand vibration, moisture, and corrosive environments

High Accuracy: Provides precise measurement for efficient performance monitoring

Explosion-Proof and IP-Rated Options: Suitable for engine rooms and hazardous zones

Corrosion-Resistant Materials: Designed for seawater and harsh chemical exposure

Digital & Analog Compatibility: Integrates seamlessly with control and monitoring systems