Types of Pressure Sensors We Supply

Be informed with the most recent developments, articles and news about our Pressure Transmitter.

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

Reliable Pressure Sensors from MTC

MTC is a trusted supplier in the Philippines of pressure sensors, transmitters, pressure gauges, and transducers, including sanitary pressure transmitters and sanitary pressure gauges. Our pressure measuring devices are designed to monitor and control pressure in tanks, pipelines, and process systems. Whether used for industrial automation, food and beverage processing, or equipment monitoring, these instruments provide accurate and stable performance across a wide range of applications throughout the Philippines.

More About Pressure Sensors

A pressure sensor is an instrument that senses a mechanical pressure and either displays this pressure, transits this pressure to another location or both.

It converts the pressure into an electrical signal, which can then be read and monitored by a control system or operator. Pressure sensors are critical components used in a wide range of industries to ensure that systems operate within safe and efficient pressure limits.

At MTC, we supply high-quality pressure sensors to meet the demands of different industries, providing solutions that combine accuracy, durability, and fast local availability for customers across the Philippines.

Stand-alone Pressure Transducer (pressure sensing part/transducer)

Simple Pressure Transmitter with output signal. With or without display.

A Wide Range of Pressure Transmitters to suit various gas liquid and steam applications.

Types of Pressure Sensors We Supply

Before considering pressure transmitters, we ought to look at some historical facts that come into play. In the early 20th century, it was far more common to see installations of pressure gages vs a pressure transmitters.

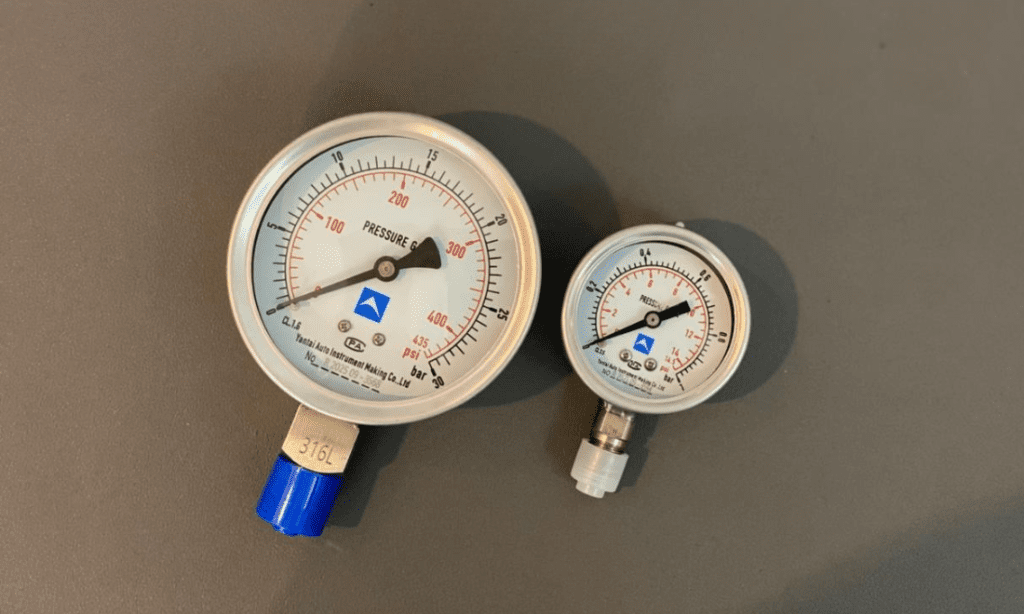

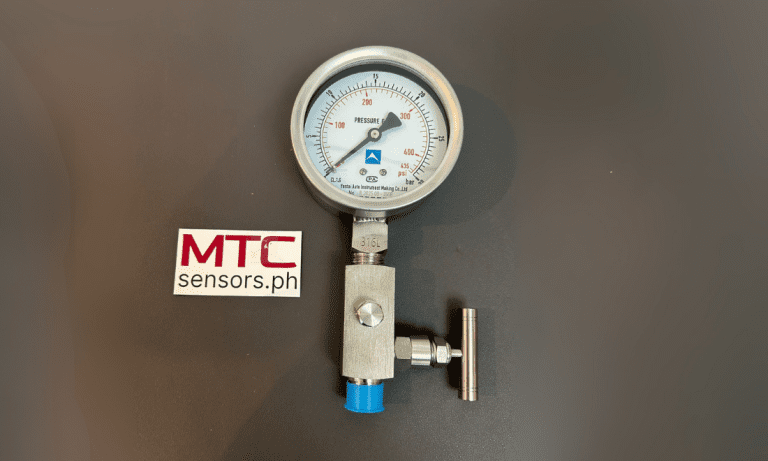

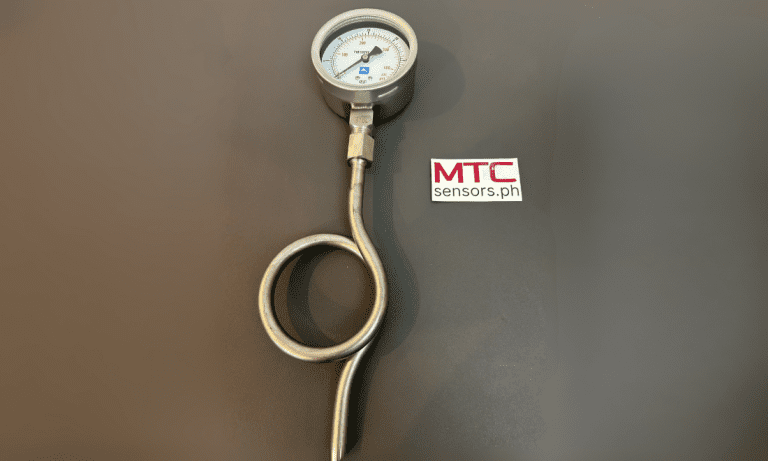

Pressure Gages are often considered to be products that use pressure to effect a mechanical piece (e.g Bourdon tube) which will indicate the pressure inside a closed system by the use of a visual pointer. These pressure gages are fabricated in different models which are designed to indicate pressure in different media of different pressure ranges and temperatures. Oftentimes where chemicals affect wetted parts, a diaphragm seal is used to isolate the gauge from the media.

Durable, Accurate, and Ready for Any Application

Our stainless steel pressure gauges are built for accuracy, durability, and corrosion resistance. Made from 316L stainless steel, they perform consistently in demanding environments—whether exposed to moisture, chemicals, or high-pressure systems.

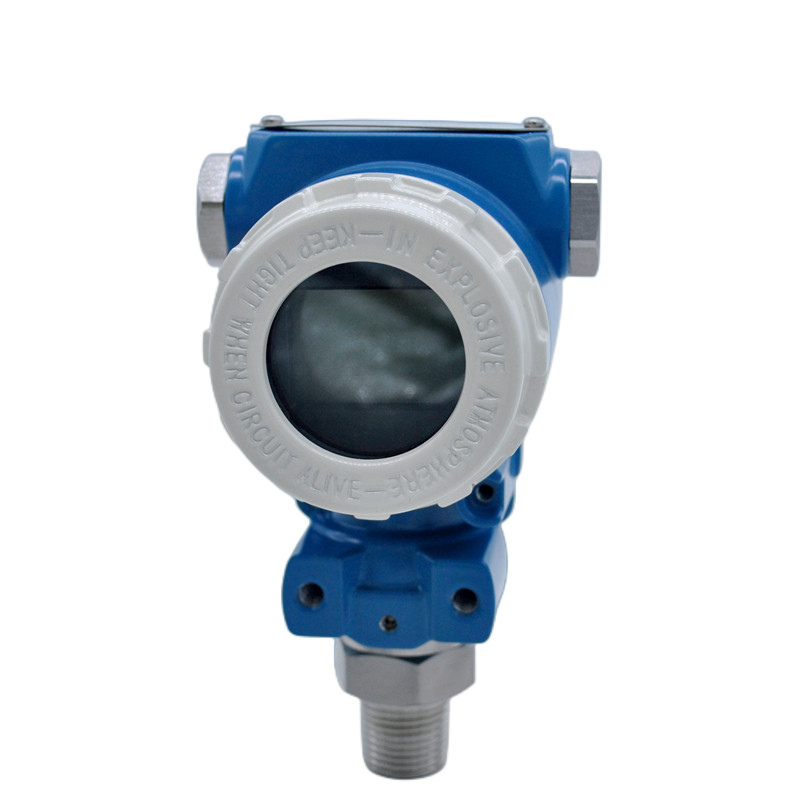

Pressure transmitters (without display) are classed differently from gauges in that they are more than often specifically designed for remote monitoring vs local indication. In more recent times it has become commonplace to buy a transmitter as well as a pressure gage since prices have come down considerably because of a wide acceptance and the mass production of compact designs. Pressure transmitters are a great plus for industries using PLC’s and dataloggers. In the same way that pressure gages have used mechanical seals to protect internal parts, the pressure transmitters can also be configured with a diaphragm type sensing element for applications that are not considered clean enough.

Since they do not have a local display, they are typically used in systems where readings are viewed or recorded remotely.

Common Rules for Pressure Transmitter selection:

After the maximum pressure value is known, it is a common practice to choose a pressure transmitter that has a range that is approximately 1.5 times the maximum pressure. It is also possible to use a slightly higher range but it must be understood that the resolution decreases if using a higher range transmitter which does not ever see a pressure that will even reach the middle of it’s range.

At all costs, it is very important never to allow a situation where a pressure port can be blocked by either a viscous liquid or dirty fluids. In these cases, consider the diaphragm type pressure transmitter which works well on corrosive chemicals, solvents and dirty fluids. If in any doubt, it is advisable to inform the supplier so that the preferred type can be used.

Always make sure that the pressure transmitter is capable of handling the temperature ranges in the process. Check with the supplier that the model selected it is suitable for your application including the accuracy expected in the given range and application.

The most common signal outputs are mA outputs designed for short distanced between controllers and signal monitors. If unsure about the distance, it is best to check the wiring/cabling distances to see whether or not some form of signal amplification is necessary. Other common signal types use voltage and frequency. In the world of instrumentation is quite common to power the devices using a 12 -24 DC voltage.

If this is a prerequisite, then it is advisable to to select pressure transmitters which use common types of connections and connectors. Unpopular connectors can often cause downtime where equipment operators who only needed a generic type of pressure transmitter are faced with having to search for products that are not readily available in the market.

Since every manufacturer is going to claim that their pressure transmitter is of exception quality, the best way to ensure a smoother operation is to always have a few spares handy, just in case.

Since there are now so many types of pressure transmitters (evidenced by a wide range to choose from ) it is often best to confer with the manufacturers or their suppliers to suggest the most appropriate type e.g silicon pressure transmitters, capacitance based pressure transmitters, crystal based types etc.

Sanitary pressure sensors, also called hygienic or 3A pressure transmitters, are designed for food, beverage, and pharmaceutical industries. They feature 316L stainless steel and polished, crevice-free surfaces that are compatible with CIP (Clean-in-Place) and SIP (Steam-in-Place) systems. These instruments are used in conjunction with pumps, filters, separators, tanks, vessels and homogenisers.

Applications: Food processing, dairy, beverage manufacturing, biopharmaceutical production.

Sanitary Pressure Gauges

Sanitary Pressure Transmitters

Sanitary Pressure Switches

At MTC, we supply a complete range of sanitary-type 3A approved instruments designed for hygienic applications in the food and beverage industry. Our products meet 3A sanitary standards, ensuring cleanability, accuracy, and reliability for critical process measurements in dairy, brewing, beverage, and food production environments.

Differential pressure sensors measure the difference between two pressure points. These are commonly used for monitoring flow, level, or filter condition.

Applications: Flow measurement across an orifice plate, filter monitoring, and tank level measurement.

Differential pressure transmitters are widely used in applications where a specific pressure drop or flow relationship is expected under normal operating conditions. When the ΔP value changes, it alerts operators that process or equipment conditions may be shifting, enabling early detection of blockages, leaks, or system inefficiencies.

MTC supplies high-quality Differential Pressure Transmitters suitable for a wide range of process, industrial, and HVAC applications. Our models are available with or without local display, and with output options to match your control system requirements.

Choosing the Right Pressure Sensor

When selecting a pressure sensor, consider the following factors:

- Type of pressure to be measured (absolute, gauge, differential)

- Pressure range and medium (gas, liquid, corrosive fluids)

- Accuracy requirements

- Operating temperature and environment

- Material compatibility (stainless steel, sanitary design, etc.)

Why Choose MTC for Pressure Measurement Instruments?

- Wide selection of pressure gauges and transmitters for industrial, process, and OEM applications

- Local and remote monitoring options available

- Technical support and application assistance from experienced engineers

- Products tested and calibrated for reliability and accuracy

- Whether you need a simple mechanical gauge or an advanced transmitter with signal output, MTC can help you find the most suitable pressure measuring device for your system.

Having trouble selecting the best instrument for your application?

Here’s a guide to help you choose the right instrument for your industry. You may also reach out to our technical team for expert guidance tailored to your specific process needs.