Level Switch

Be informed with the most recent developments, articles and news about our Level Switch.

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

Level Switch Supplier in Philippines

Available Products:

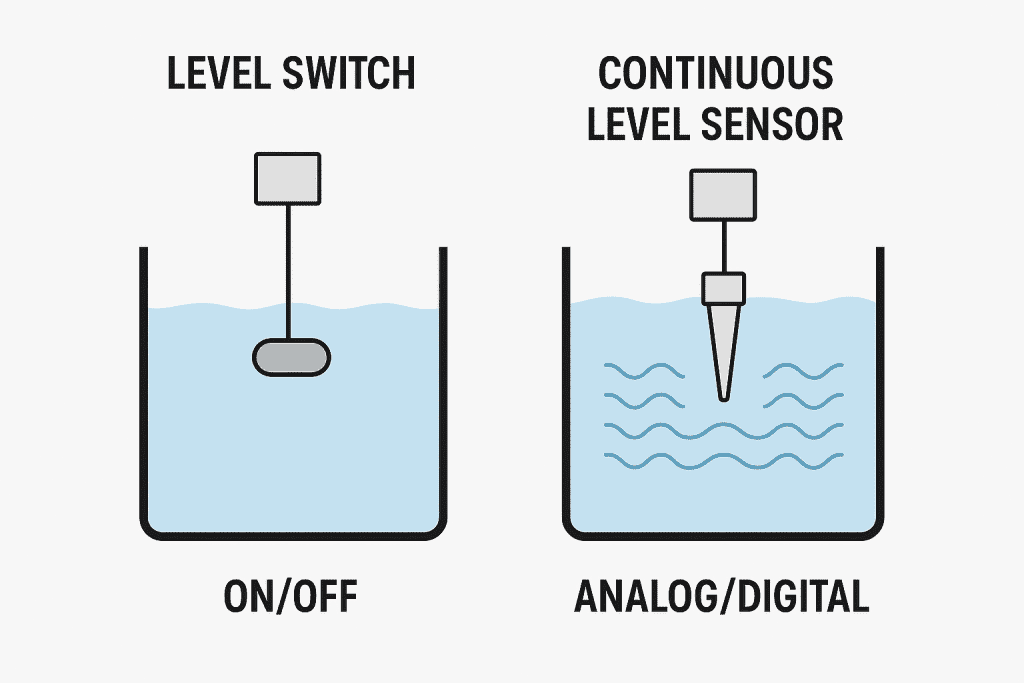

Level Switches and Continuous Level Sensors

Monitoring and controlling material levels in tanks, silos, or process vessels is essential for safe and efficient operation. Two common technologies used in industrial applications are Level Switches and Continuous Level Sensors. While both serve to detect or measure material levels, they function differently depending on the process requirements.

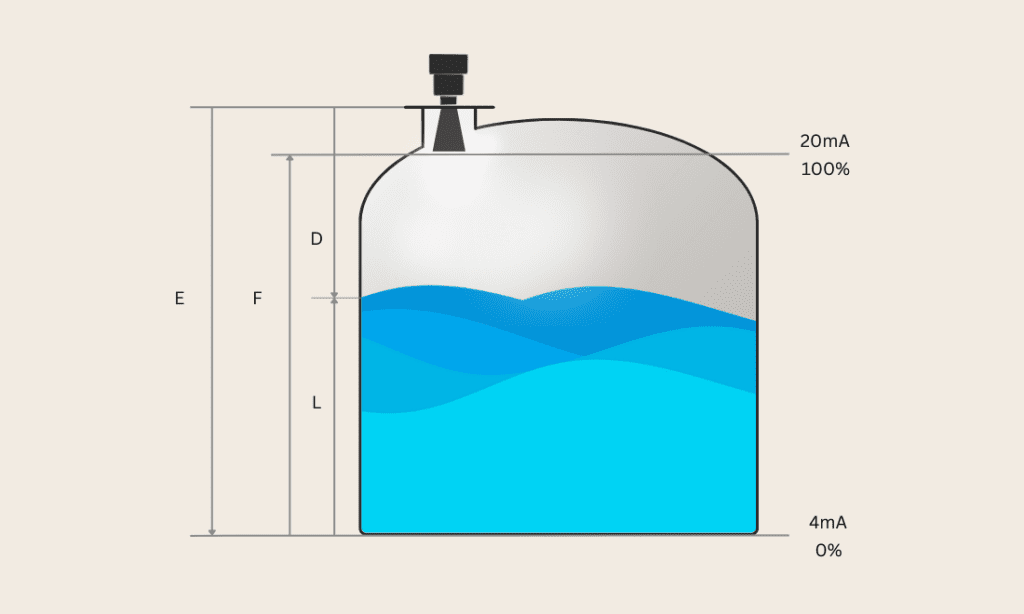

A continuous level sensor provides real-time, analog or digital measurement of the level of liquids, solids, or slurries across the full height of a tank or silo. Unlike level switches, continuous sensors give an accurate and proportional reading of the actual level.

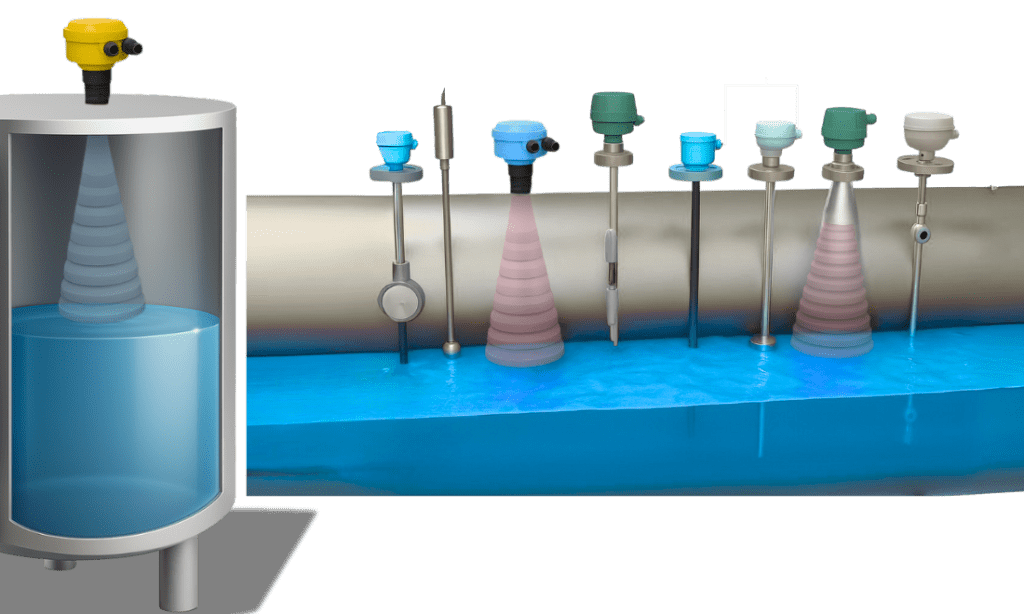

A Radar Level Gauge is an advanced type of continuous level measurement instrument that uses microwave radar technology to accurately monitor the level of liquids, slurries, or bulk solids — even under harsh process conditions. It provides real-time, contactless measurement, ensuring reliable and maintenance-free performance for industrial applications.

Level Sensors

What are Level Switches?

A level switch (often called a level sensor) is a device often installed in certain tanks, containers and vessels to trigger an alarm when the solid or liquid in the storage device reaches a certain level. Using a PNP/NPNM output or a relay it can also start of stop the discharging of a material or a fluid if connected to some type of solid state or programmable logic controller.

Are Level Switches Used for Monitoring Intermediate Levels in a Tank?

No! Level switches are not designed to measure continuous level, however, many continuous level devices also have options to act as level switches. If this is the case, then why opt for a level switch? The reason to buy a level switch is often economic reasons. A level switch often costs less than a level transmitter. In addition, a level switch is often much easier to understand and install.

What are some different types of level switches popular in the industry? Some of the most common types which are widely used are:

There are other types of level switches in use for special applications in a process that requires. The selection of level switch types is often based on the existing technology in use. If the existing type of level switch has been found to be reliable over extended periods with little maintenance required it is common for operators to keep using the same type of switch.

- Rotating Paddle Level Switches

- Capacitance Type Level Switches

- Vibrating Fork Level Switches

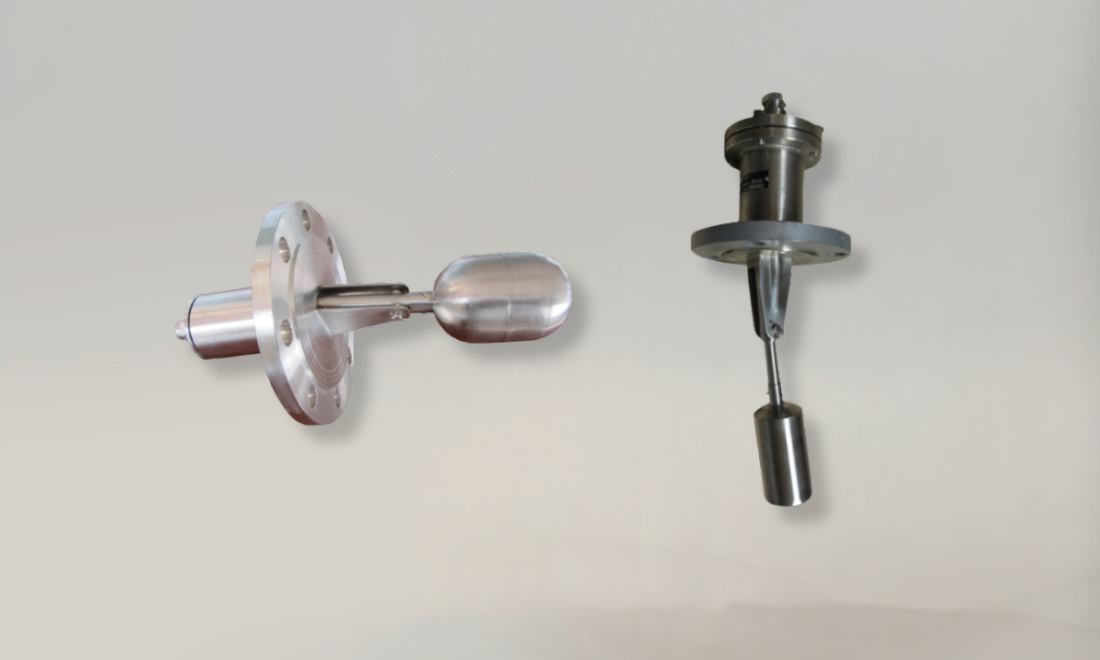

- Float Level Switches

- Conductive Type Level Switches

- Ultrasonic Type Level Switches

- Pressure Based Switches

How does a vibrating fork level switch work?

A vibrating fork level switch operates by using a pair of prongs (the “fork”) that vibrate at a specific frequency. When the fork comes into contact with a liquid or solid material, the frequency of the vibration changes. This change is detected by the internal electronics, which then trigger a signal, such as an alarm or a control action, to indicate the presence of material.

For more information, please watch the video below!

Having trouble selecting the best instrument for your application?

Here’s a guide to help you choose the right instrument for your industry. You may also reach out to our technical team for expert guidance tailored to your specific process needs.