Electrostatic Precipitator Malfunction Sensors

These sensors provide real-time detection of sparking, short circuits, rapping faults, and electrical anomalies — ensuring safe, efficient, and compliant operation of ESP systems.

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

What are Broken Bag Detectors?

Broken Bag Detectors are designed to provide a safe and reliable means of detecting leaks and failures in industries that specialize in handling powder and bulk solids. The bag leak detectors are used in a large variety of applications which require detection of dust particles as part of maintenance or environmental requirements. The detection of leaks in a bag house’s filters can be critical to a plant’s operations.

- Power/electricity generation

- Cement industry

- Chemicals industry

- Metals industry

- Paper industry

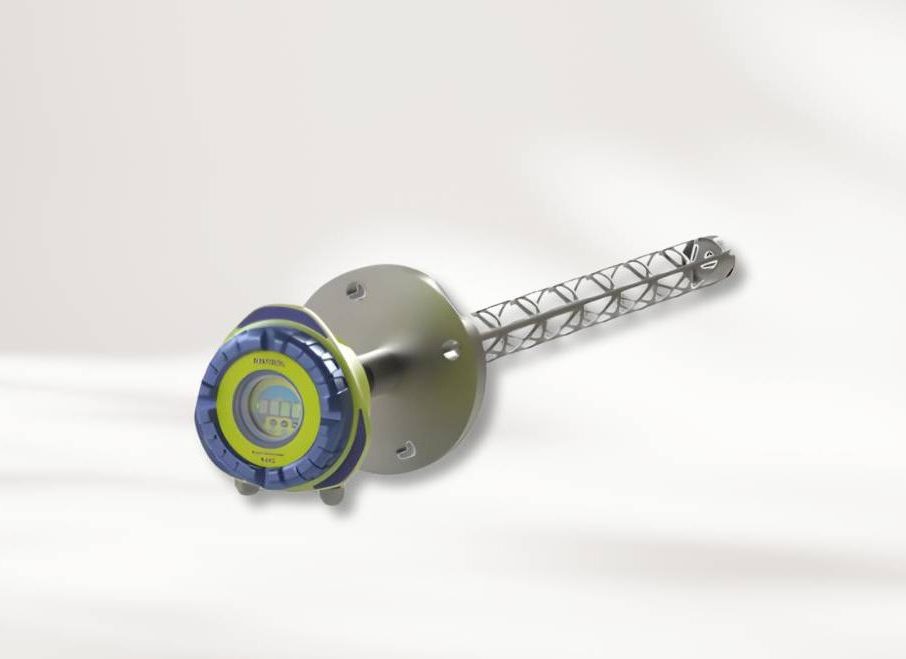

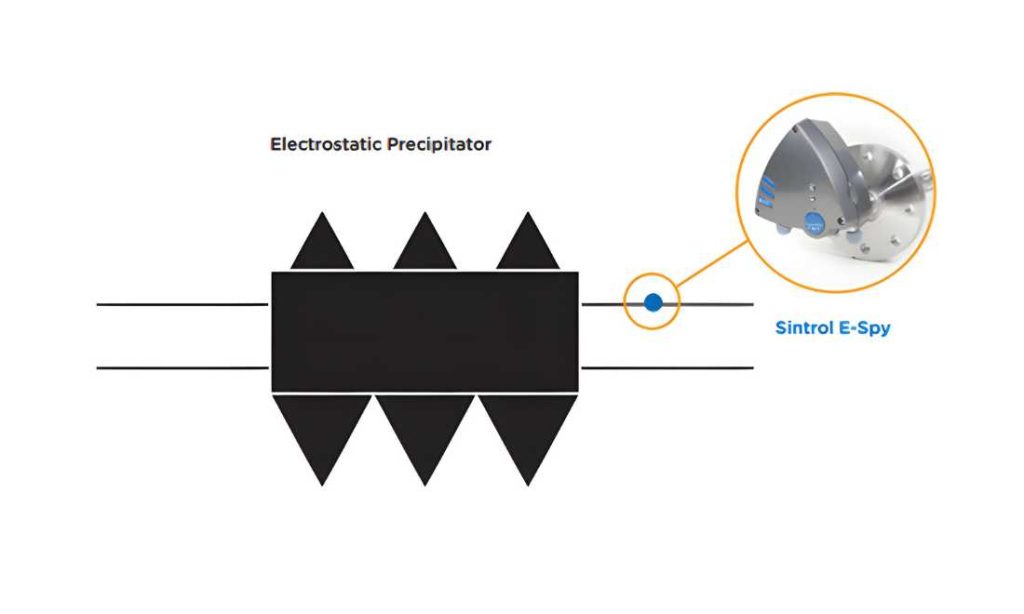

What are dust monitors for electrostatic precipitators?

Dust monitors are used to detect changes in dust loading due to bag filter breakage or electrostatic precipitator (ESP) malfunction.

Steel companies need to monitor the relative trend of dust after its ESP in the sintering plant. During the sintering process, water vapors along with corrosive compounds such as SO2 and H2S are created along with dust particles. This created multiple challenges in finding the right solution. With a normal probe, the chemicals would likely stick to the probe and corrode the steel away. The water vapors would also aff ect the dust concentrations if it reached the enclosure carrying the electronics. Since the measuring point is immediately after the ESP, the charge of the electrostatic field must also be neutralized.

Get in touch with us for more information on our unique sensor. This consists of a modified S303 monitor along with a faraday cage. The faraday cage helps neutralize the electrostatic field created by the ESP enabling the monitor to gather an accurate relative trend measurement.

Other applications:

- Monitoring of dust content in exhaust air of a tablet pressing machine

- Monitoring of cement dust in clean gas channel

- Monitoring of air quality in a Pharma company

- Filter Damage Monitoring in Clean Gas Channel

Having trouble selecting the best instrument for your application?

Here’s a guide to help you choose the right instrument for your industry. You may also reach out to our technical team for expert guidance tailored to your specific process needs.