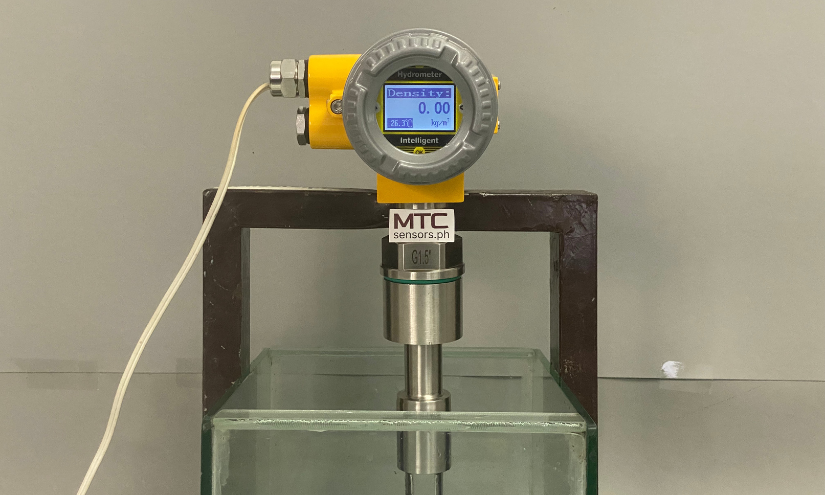

Liquid Density Meters - Tuning Fork Densitometers

MTC’s Liquid Density Meters are designed for continuous, real-time monitoring with high stability, accuracy, and repeatability — even under varying temperature and pressure conditions.

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

What is a Density Meter?

Density measurement is an important measurement parameter for all kinds of industries, this includes food and beverage, mineral processing e.g clay, carbonates and silicates. Density monitoring and detection of density is also very useful to process engineers monitoring reactors and separators.

MTC is a supplier in the Philippines of easy to use and economically priced density measurement solutions. In this case, the product is using a tuning fork principle which is well known and widely adapted for accurate measurements of liquid density combined with automatic temperature compensation. A standard measuring range is from 0-2500 kg/m^3 with a maximum temperature of 150 degrees celsius. The only drawback is that the application must not exceed a maximum velocity if it installed in a pipeline. In cases where process constraints such as high velocities, temperatures and pressure exceed the limitations of the device, the user can opt for a different principle of operation. However, the resonant frequency style sensor is going to be adequate for a wide range of applications.

The Importance of Density Measurement Across Industries

Density measurement is a critical parameter in many industries, as it helps ensure product quality, consistency, and process efficiency. It is widely used in:

- Food and Beverage Processing – To monitor the concentration of liquids such as syrups, juices, dairy products, and alcoholic beverages.

- Mineral Processing – Essential for measuring the density of clay, carbonates, silicates, and other minerals in slurry-based applications.

- Chemical and Pharmaceutical Industries – Used in reactors and separators to maintain accurate formulations and prevent process inefficiencies.

- Oil and Gas Sector – Helps measure crude oil density, fuel mixtures, and refinery process flows.

- Water and Wastewater Treatment – Plays a role in monitoring sludge concentration and optimizing treatment processes.

In industrial operations, density monitoring is crucial for process engineers, as it enables real-time control of fluid composition, separation efficiency, and overall process stability.

The Importance of Density Measurement Across Industries

Range: 0-3g /cm2

Powered: 24 VDC

Material: SS304 or SS316

Output: 4-20mA RS485 Modbus

Connect: Tri clamp, Thread, Flange

Application

- Food and Beverage Industry

- Process Control System

- Chemical Industrial

- Pharmaceutical Industry

- Environmental Monitoring

Having trouble selecting the best instrument for your application?

Here’s a guide to help you choose the right instrument for your industry. You may also reach out to our technical team for expert guidance tailored to your specific process needs.

Regardless of your process requirements, MTC can help you select the most suitable density measurement solution for your industry. Contact Us Now!