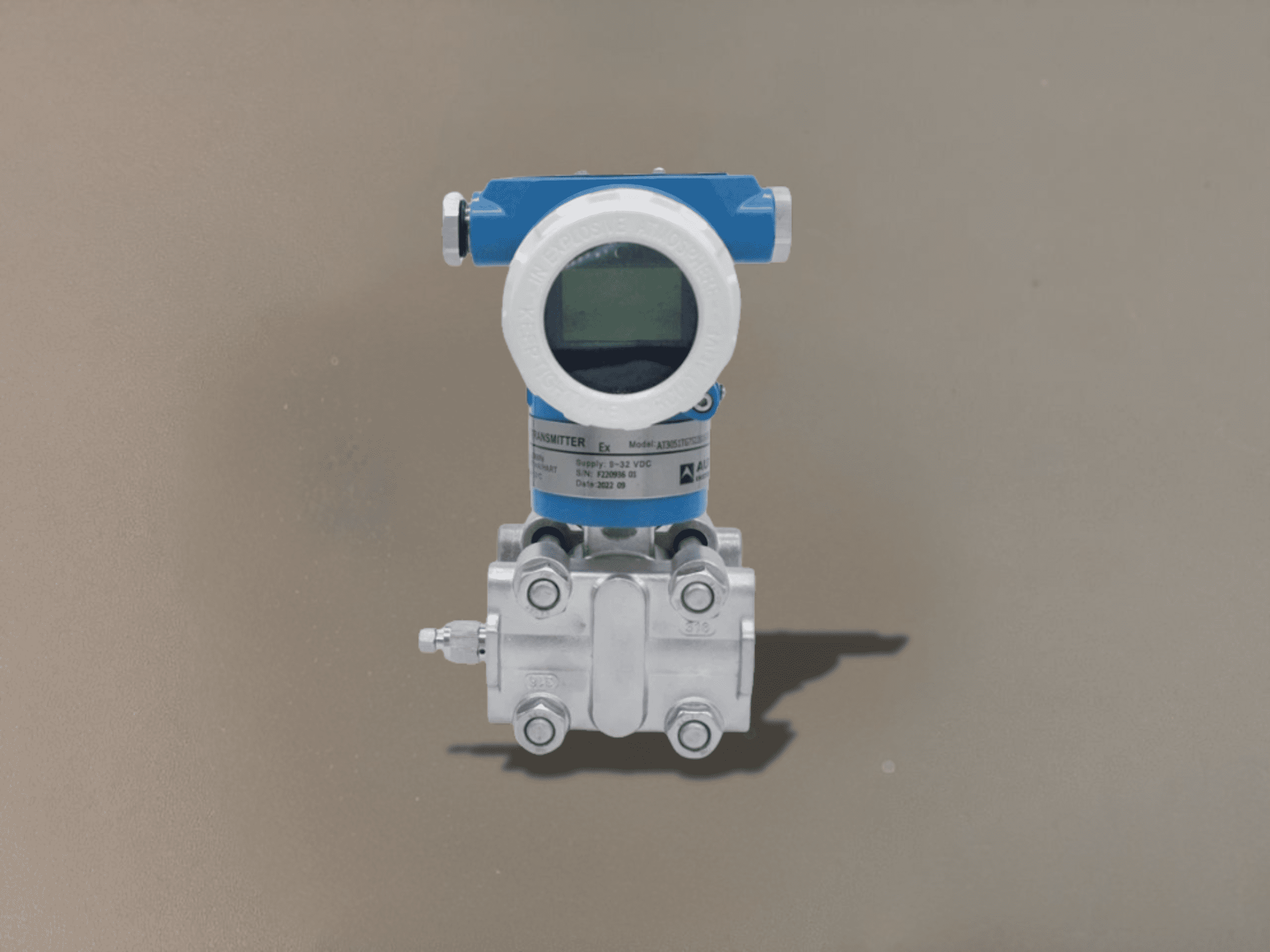

Pressure Transmitter

Used to measure pressure in gases or liquids and convert that pressure into an electrical signal (commonly 4–20 mA or a digital output) that can be read by controllers, indicators, or monitoring systems.

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

Pressure Transmitter Supplier in the Philippines

Available Products:

What is a Pressure Transmitter?

A pressure transmitter is an instrument that measures pressure and converts it into an electrical signal (typically 4–20 mA or digital output) that can be sent to controllers, displays, or data acquisition systems. This allows continuous and remote monitoring of process conditions in industrial systems.

Measurement Technologies Corporation (MTC) supplies high-quality pressure transmitters designed for accurate and reliable measurement of pressure in gases, liquids, and steam. Our transmitters are used in a wide range of industries — from manufacturing and process control to water treatment, HVAC, and power generation — ensuring stable and precise readings even in demanding environments.

Types of Pressure Transmitters We Supply

- Pressure Transmitters (Compact Type) – Built with robust stainless-steel construction and advanced sensing elements, it ensures dependable operation even under harsh industrial conditions.

- Differential Pressure Transmitters – Measure the pressure difference between two points, commonly used for flow or level measurement.

The Compact Type Pressure Transmitter converts pressure from gases or liquids into a standardized electrical signal — typically 4–20 mA or 0–10 V — for monitoring and control. Built with robust stainless-steel construction and advanced sensing elements, it ensures dependable operation even under harsh industrial conditions.

Why is it Compact?

The Compact Type Pressure Transmitter is designed to deliver accurate pressure measurement in a smaller, lighter form factor — without sacrificing performance. Its compactness comes from:

Integrated Design: The sensor, amplifier, and signal conditioning electronics are built into a single housing, eliminating the need for a bulky external transmitter body.

Miniaturized Components: Advances in microelectronic technology allow for smaller sensing elements and low-power circuitry, reducing both the size and weight of the transmitter.

Simplified Mounting: The compact body fits easily into tight installation spaces — ideal for OEM machines, mobile systems, or equipment with dense piping layouts where standard transmitters may not fit.

Reduced Installation Footprint: Compact transmitters typically feature direct process connections (such as threaded or flush diaphragm types), so they don’t require additional manifolds or brackets.

Lightweight but Durable: Despite being smaller, they retain industrial-grade materials like stainless steel or aluminum alloy for protection against vibration, corrosion, and pressure spikes.

A Differential Pressure (DP) Transmitter measures the difference between two pressure points and converts that difference into a standard electrical output signal, such as 4–20 mA or digital communication (HART or Modbus).

By comparing the high-pressure (HP) and low-pressure (LP) sides, it can calculate pressure variations that indicate fluid flow, tank levels, or pressure drops across filters, pipes, or orifices.

Why is it Called “Differential” Pressure Transmitter?

It’s called “differential” because this type of transmitter measures the difference between two pressure points — rather than a single, absolute, or gauge pressure.

A Differential Pressure (DP) Transmitter has two pressure ports:

High-Pressure (HP) side

Low-Pressure (LP) side

The transmitter continuously compares the pressure applied to these two ports and calculates the difference (ΔP = HP – LP). This differential value is then converted into an electrical signal (commonly 4–20 mA) that represents the measured pressure difference.

Applications

- Flow Measurement: Using orifice plates, venturi tubes, or flow nozzles.

- Level Measurement: For closed or pressurized tanks.

- Filter Monitoring: Detecting pressure drops to signal clogging.

- HVAC Systems: Monitoring air filters and duct pressure differences.

- Process Control: For chemical, water, and power industries.

- OEM Equipment: Compact integration into skids or mobile systems.

Advantages

- Saves space while delivering high accuracy

- Easy to install and integrate with existing systems

- Reliable differential pressure readings

- Ideal for both gas and liquid applications

- Designed for harsh and industrial environments

Why Choose MTC

At Measurement Technologies Corporation (MTC), we supply Wide Range of Pressure Transmitters that meet industrial standards for precision, durability, and stability. Every unit is tested and calibrated to ensure long-term reliability in your process system.

We also provide local technical support, calibration services, and fast delivery across the Philippines — ensuring you get the right product for your specific application.

Having trouble selecting the best instrument for your application?

Here’s a guide to help you choose the right instrument for your industry. You may also reach out to our technical team for expert guidance tailored to your specific process needs.