Measuring Thickness of Various Materials

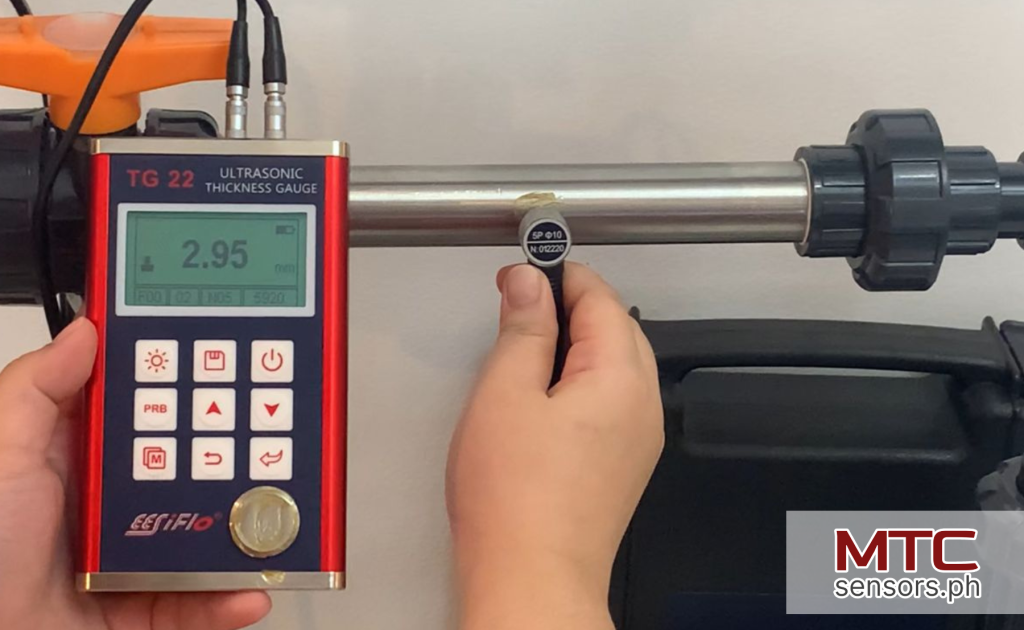

Ultrasonic thickness gauges are advanced instruments used to measure the thickness of materials ranging from metals and plastics to composites and ceramics.

Filter by Category

Product Collection

Ultrasonic Thickness Gauge

More About Ultrasonic Thickness Gauge

MTC Sensors PH is a trusted supplier of high-quality thickness gauges in the Philippines, catering to the diverse needs of various industries. Whether you require precision measurement for metal sheets, coatings, plastics, or fragile materials like glass, MTC Sensors PH provides reliable solutions to ensure accuracy and efficiency in your processes.

Their range includes advanced ultrasonic thickness gauges, ideal for non-destructive testing, and coating thickness gauges for monitoring paint and plating applications. With a commitment to quality and customer satisfaction, MTC Sensors PH ensures that their products meet the highest industry standards, making them a dependable partner for businesses in manufacturing, construction, automotive, and more.

If you’re in need of thickness gauges for your projects, MTC Sensors PH offers both expertise and competitive pricing to help you find the best solution for your specific application.

How Does a Ultrasonic Thickness Gauge Work?

Other Products

EASZ-1 Water Cut Analyzers

2-Wire Loop Powered Water-Cut Monitor Overview Features & Benefits Specifications Overview The EASZ-1 is a hazardous area approved online monitor