Understanding Ultrasonic and Radar Level Sensors

This guide breaks down their differences, strengths, limitations, and ideal applications to help you choose the right level measurement solution for your operation.

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

A Complete Guide to Ultrasonic and Radar Level Sensor

Accurate level measurement is essential for safety, process efficiency, and equipment protection across many industries. Two of the most widely used non-contact technologies today are the ultrasonic level sensor and the radar level gauge. While both devices measure the level of liquids or solids without touching the material, they work differently and offer unique advantages.

What is an Ultrasonic Level Sensor?

An ultrasonic level sensor measures level by sending high-frequency sound waves toward the surface of the material. The time it takes for the echo to return determines the distance, allowing the device to calculate the level.

Advantages

- Economical and cost-effective

- Simple installation and setup

- Ideal for non-critical and general-purpose applications

- Works well for water, wastewater, and non-corrosive liquids

Limitations

- Performance affected by dust, steam, vapor, foam, and temperature changes

- Not ideal for pressurized or high-temperature tanks

- Requires a clear and unobstructed measurement path

Ultrasonic sensors are suitable for facilities that require affordable, straightforward level monitoring without extreme environmental challenges.

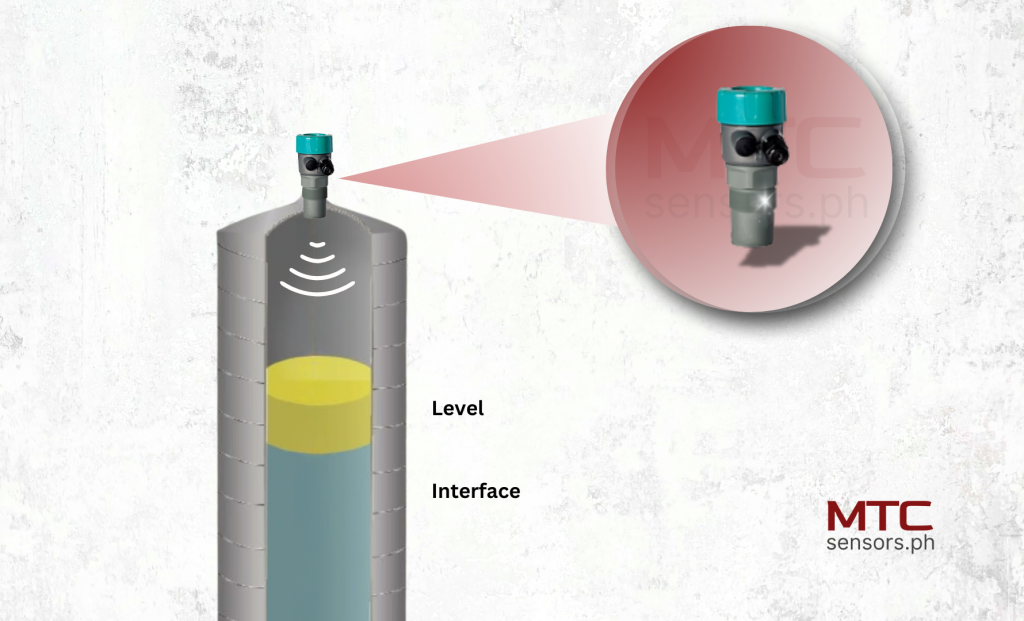

What is an Radar Level Sensor?

A Radar Level Sensor uses microwave radar waves instead of sound. These waves travel at the speed of light, reflect off the surface of the medium, and return to the sensor. Radar is known for its high accuracy and ability to perform in harsh or changing process conditions.

Advantages

- Very high accuracy and stability

- Unaffected by steam, dust, foam, pressure, or temperature

- Suitable for complex tanks, tall vessels, and bulk solid applications

- Low maintenance—no contact with product

Works with corrosive, viscous, or hazardous materials

Limitations

- Higher initial cost compared to ultrasonic

Requires proper installation placement to avoid internal obstructions

Key Differences Between Ultrasonic and Radar Sensors

| Feature | Ultrasonic Level Sensor | Radar Level Sensor |

|---|---|---|

| Measuring Principle | Sound waves | Microwave radar waves |

| Accuracy | Moderate | High to very high |

| Environmental Sensitivity | Affected by vapor, dust, foam, temperature | Stable in harsh conditions |

| Suitable For | Clean, simple applications | Complex, harsh, extreme environments |

| Best Media | Water, wastewater, benign liquids | Solids, chemicals, oils, powders, corrosive liquids |

| Cost | Lower | Higher |

| Maintenance | May require cleaning | Very low |

Which Sensor Should You Choose?

For basic, low-cost, and clean applications, pick an Ultrasonic Level Sensor.

For demanding, high-performance, and industrial environments, a Radar Level Sensor is the smarter choice.

Both technologies are effective—the best option depends on your specific tank design, material type, and environmental conditions.

When to Use a Ultrasonic Level Sensor:

Choose ultrasonic if your application is:

- Clean, simple, and cost-sensitive

- Involving water, wastewater, or light industrial liquids

- At normal atmospheric pressure

- Free of heavy dust, steam, or vapor

Common Industries:

Water treatment, agriculture, food processing (non-harsh), municipal storage tanks.

When to Use a Radar Level Sensor:

Choose radar if you need:

- High accuracy and reliability

- Operation in dusty, steamy, pressurized, or high-temperature conditions

- Measurement of solids, powders, viscous or corrosive liquids

- Long-distance measurement in tall tanks or silos

Stable level detection despite foam or condensation

Common Industries:

Cement and construction, chemical processing, oil & gas, power generation, mining, grain and feed storage, food and beverage manufacturing.

We supply a full range of ultrasonic and radar level solutions designed for every industry—from water treatment to oil & gas, food processing, chemical storage, cement, and more.

Having trouble selecting the correct pressure instrument for your application?

Here’s a guide to help you choose the right instrument for your industry. You may also reach out to our technical team for expert guidance tailored to your specific process needs.