Ultrasonic Level Sensor

Ultrasonic Level Transmitters are designed for durability, accuracy, and reliability, making them an excellent choice for a wide range of industrial applications.

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

Product Collection

Ultrasonic Level Transmitters

More About Ultrasonic Level Transmitters

With measurement ranges up to 40 feet, short dead bands, and optional display features, these transmitters offer precise and efficient level monitoring for various liquid storage and processing needs. A solution that enhances operational efficiency, ensures safety, and delivers precise level measurements every time.

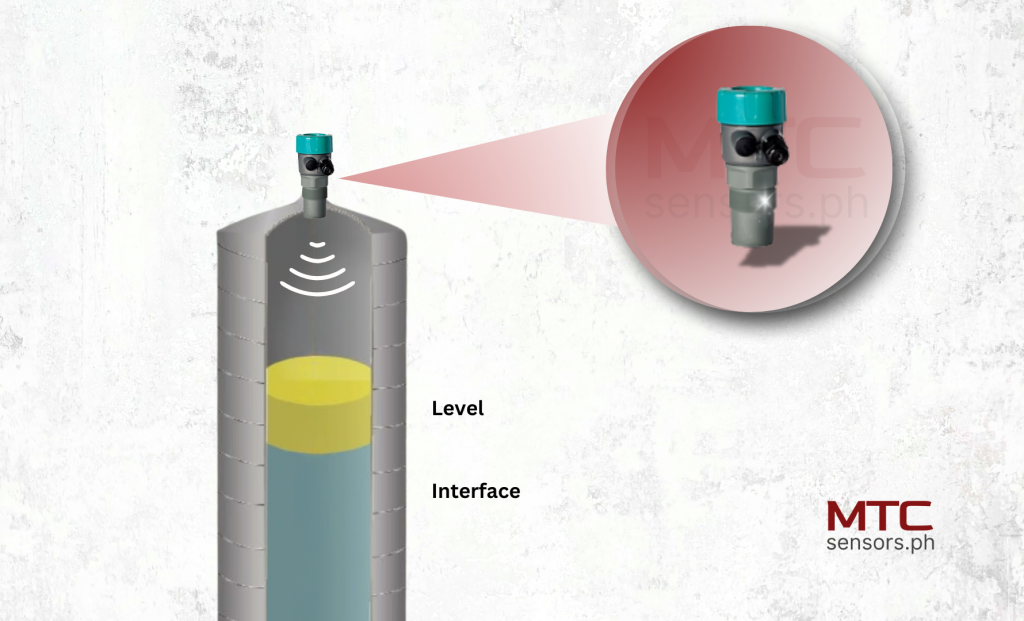

An ultrasonic level sensor is a non-contact device that measures the level of liquids, slurries, or solids using high-frequency sound waves. It is commonly used in industrial applications where reliable and maintenance-free level measurement is required.

- Liquid Level Measurement – Tracking fluid levels in tanks and reservoirs.

- Solid Level Detection – Measuring powders, grains, and bulk materials.

- Distance Measurement – Detecting object distances in automation systems.

- Flow Monitoring – Measuring the height of liquid in open channels to calculate flow rates.

- Presence Detection – Used in parking systems, robotics, and obstacle detection.

- The ultrasonic level meter operates on the Time-of-Flight (ToF) principle:

- The sensor emits high-frequency sound waves toward the material surface.

- These waves reflect off the surface and return to the sensor.

- The system calculates the distance based on the time taken for the waves to return.

- The level reading is displayed or transmitted to a control system.

Since it is non-contact, it is ideal for corrosive, hazardous, or sanitary applications.

- Tank Level Monitoring – Used in industrial storage tanks to measure liquid levels.

- Silo & Hopper Measurement – Tracking bulk solids such as grains, powders, and cement.

- Water Management – Monitoring water levels in rivers, reservoirs, and treatment plants.

- Industrial Automation – Used in robotics for obstacle detection and positioning.

- Vehicle Parking Systems – Detecting vehicle proximity for automated parking.

- The sensor emits high-frequency sound waves (ultrasonic pulses) toward the material surface.

- The pulses reflect back when they hit the surface.

- The sensor calculates the distance based on the time delay (Time-of-Flight principle).

- The level reading is displayed or transmitted to a control system for monitoring and automation.

Since ultrasonic sensors rely on sound waves, they do not require physical contact with the material, reducing wear and contamination risks.

Need assistance choosing the right Ultrasonic Level Transmitters? Contact us today for expert recommendations and fast delivery!

Other Products

Sultan Sonar System

Overview Features & Benefits Applications Specifications Overview The HAWK Sultan Sonar uses Advanced Sonar Technology to measure and control Waste

ORCA Bed Level System

Overview Features & Benefits Applications Specifications Overview The ORCA Sonar Bed Level System will measure up to two density interfaces

OptioLaser L200

Overview Features & Benefits Applications Specifications Overview The OptioLaser L200 is a non-contact laser sensor used to measure the distance

MiniWave Ultrasonic Level Transmitter

Overview Features & Benefits Applications Specifications Overview The MiniWave is a compact, loop-powered ultrasonic level transmitter for continuous measurement of

HawkUltra Plus Ultrasonic Level Transmitter

Overview Features & Benefits Applications Specifications Overview The HawkUltra Plus HUPT Ultrasonic Level Transmitter provides non-contact level measurement up to