Hand-held, Portable, Easy-to-Operate Ultrasonic Thickness Gauge

The model TG22 is a digital thickness gauge which based on the ultrasonic measurement principle. The instrument is capable of measuring the thickness with various materials, such as metal, plastic, ceramic, glass and many other materials which are ultrasonic conductive.

With the alternative mode, it can measure the velocity of all kinds of materials to get the respective material identical sound velocity. Compared with the traditional measurement methods, the advantage of an ultrasonic thickness gauge is exposed to one side of the workpiece to complete the measurement without affecting any process under operation. The instrument is as easy to use with just applying the acoustic coupling compound to the probe surface, which then is placed firmly on the workpiece.

The wall thickness displayed can be stored directly in the transmitter for later data-logged retrieval. Its’ unique non-destructive testing performance provides the perfect solution for the thickness testing of closed pipes, containers, pressure vessels, etc. It is widely used for petroleum, chemical, metallurgy, shipbuilding, aviation, aerospace, and other industry because of quality control, production, and inspection purposes.

- Large back lit LCD Display

- Rugged Hand-held design

- Zero point calibration, two-point calibration, automatic error correction system

- Coupling status indicator

- Auto Sleep and auto power off function to conserve battery life

- Small, portable, high reliability for harsh operating environment, anti- vibration, antishock and anti-electromagnetic interference

- Pipelines

- Storage tanks

- Lighting Columns

- Road Tankers

- Bridges

- Pressure Vessel

Capable of performing measurements on a wide range of material, including:

- Metals

- Plastic

- Ceramics

- Composites

- Epoxies

- Glass

- And other ultrasonic wave well-conductive materials.

EESIFLO: TG22

Design: Field instrument with 1 measuring channel

Transducers: EES-N05/90⁰ (Standard Supply)

MEASUREMENT

Measurement Principle: Transit time difference correlation principle (pulse/echo)

Measuring Range: mm 0.75…300 (in steel)

Sound Velocity: m/s 300…19999

Resolution: mm 0.1 / 0.01

Measurement Frequency: Single-point measurement 4/s, Scan Mode 10/s

Accuracy: ± 0.5% of reading ( ± 0.01mm thickness)

TRANSMITTER

Power Supply: Two “AA” Size, 1.5 volt alkaline batteries

Memory Capacity: Memory for 100 files (up to 100 values for each file) of stored values

Alarm Function: Upper and lower limit can pre-set. It alarms automatically when the result value exceeding the limit

Working Time: 100 hours typical operating time (EL backlight off)

Housing Material: Extruded aluminium body suitable for use under harsh environment

Dimension: mm 130 x 76 x 32

Weight: g 345

Ambient Temperature: ⁰C -10…+50

Display: 4.5 digit LCD with EL backlight

Menu Language English, German, French, Spanish, Italian

COMMUNICATION (OPTIONAL)

Interfaces: USB 2.0

Measuring Principle

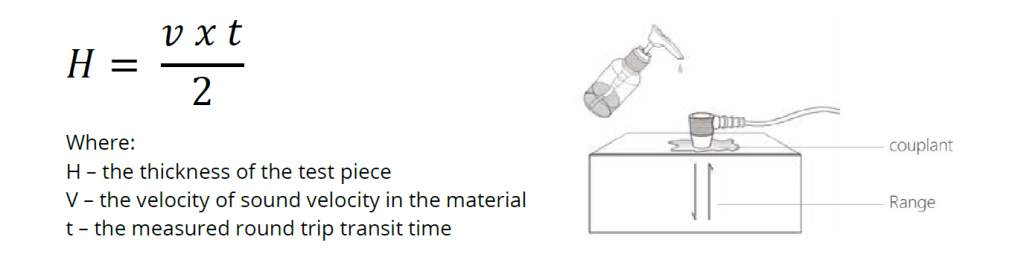

The digital ultrasonic thickness gauge determines the thickness of a part or structure by accurately measuring the time required for a short ultrasonic pulse generated by a transducer to travel through the thickness of the workpiece, and the sound waves are coupled into the test material and travel through it until they encounter a back wall or other boundaries. The reflections then travel back to the transducer, which converts the sound energy back into electrical energy. In essence, the gauge listens for the echo from the opposite side. Typically this time interval is only a few millionths of a second. The gauge programmed with the speed of sound in the test material, from which it can then calculate thickness using the simple mathematical relationship.

To make sure the gauge working properly, it needs to use coupling compound to fill the gaps between the

transducers surface and the measured workpiece surface.

Optional Spare Transducer Selection