Sanitary 3A Certified Instruments

These instruments are specifically designed for applications that require strict sanitary compliance — such as food and beverage production, dairy processing, pharmaceuticals, and biotechnology.

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

Instrumentation for the Sanitary Industry

MTC works with some of the leading players in supplying instruments to the food processing industry and the pharmaceutical industry, where high demands for hygiene are present. We offer a comprehensive product range for measuring pressure and temperature in all kinds of hygienic applications in the Philippines. These instruments are used in conjunction with pumps, filters, separators, tanks, vessels and homogenisers.

We supply diaphragm seals from Tempress which are characterized by very high accuracy and long-life cycles. The diaphragm seals fulfill the highest hygienic standards and are made in accordance with international standards such as ISO, DIN, ASME, RJT, IFD and many others. Moreover, many of the designs are approved by 3-A, reg. no 641.

Tempress’ diaphragm seals for hygienic purposes are well documented and can be supplied with:

- 2.2 material certificates

- 3.1 traceability certificates

- Calibration certificates

Tempress’ diaphragm seals are only filled with transmission liquids that conform to USP/FDA/BP/HP EURO/DAB/E422/FCC III and Japanese pharmacopoeia standards.

Sanitary 3A Approved Instruments for Food & Beverage Applications

At MTC, we supply a complete range of sanitary-type 3A approved instruments designed for hygienic applications in the food and beverage industry. Our products meet 3A sanitary standards, ensuring cleanability, accuracy, and reliability for critical process measurements in dairy, brewing, beverage, and food production environments.

Why Choose 3A Sanitary Instruments?

3A-approved instruments are specifically engineered to meet the strict hygiene and safety standards required in food and beverage processing. These instruments feature stainless steel construction, smooth polished surfaces, and crevice-free designs to prevent contamination and allow for easy cleaning during CIP (Clean-in-Place) and SIP (Steam-in-Place) processes.

Our Range of Sanitary 3A Instruments

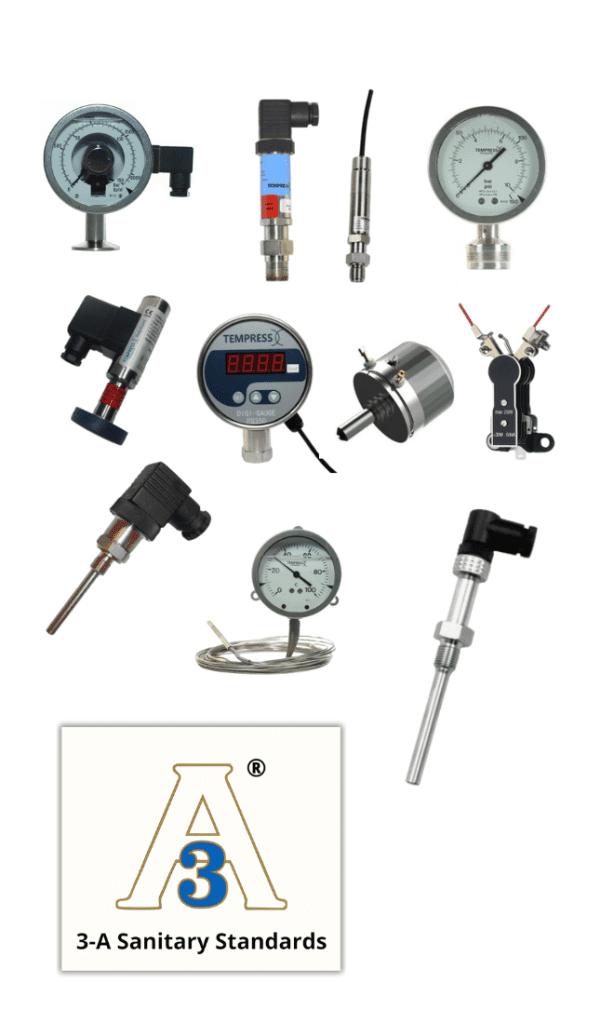

Sanitary Pressure Gauges

Our 3A sanitary pressure gauges are built with 316L stainless steel diaphragms and tri-clamp connections, ideal for measuring pressure in milk, juice, beer, and other liquid processes. They deliver precise readings while maintaining the highest levels of hygiene.

Sanitary Pressure Transmitters

Designed for accuracy and durability, our sanitary pressure transmitters feature flush diaphragms and FDA-compliant materials, making them suitable for pasteurization systems, mixing tanks, and filling lines. They ensure stable output even under frequent cleaning cycles.

Sanitary Pressure Switches

Our 3A pressure switches provide reliable pressure control for hygienic applications. These switches are designed to withstand washdowns and maintain accuracy in demanding food and beverage processing conditions.

Sanitary Temperature Gauges & Sensors

We offer sanitary temperature gauges, RTDs, and thermowells that comply with 3A standards. Perfect for monitoring temperature in fermentation tanks, pasteurizers, and storage vessels, they ensure product safety and process efficiency.

Having trouble selecting the best instrument for your application?

Here’s a guide to help you choose the right instrument for your industry. You may also reach out to our technical team for expert guidance tailored to your specific process needs.