- atmospheres

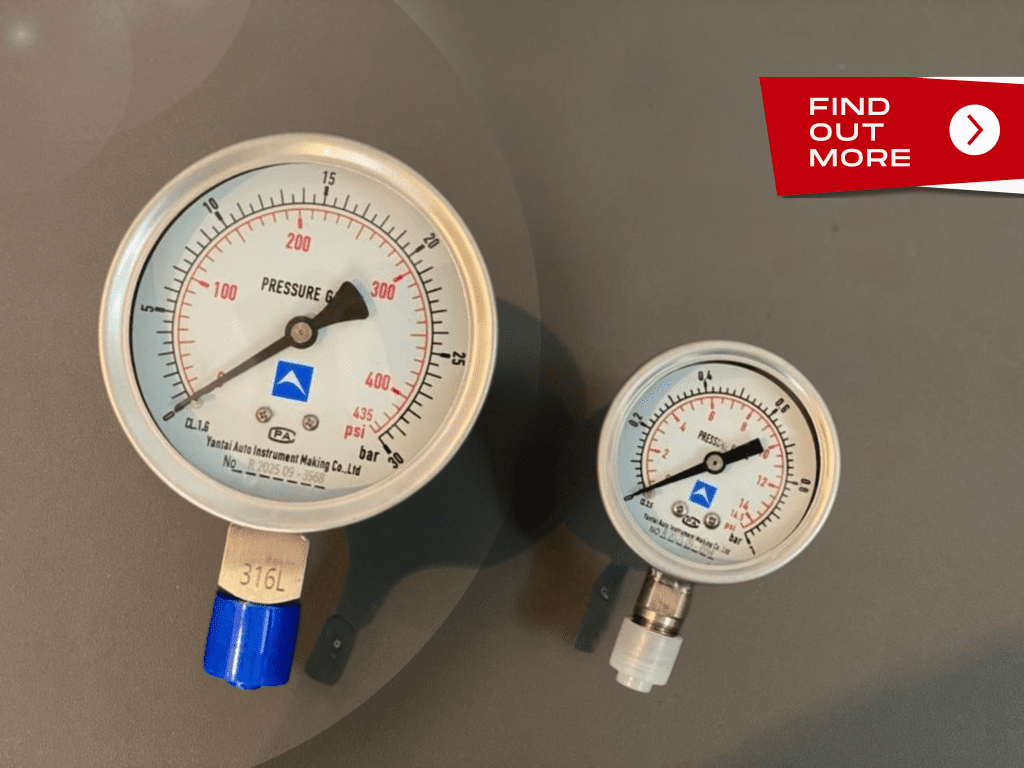

- bars

- centimeters mercury

- centimeters water

- feet of water

- hectopascals (hPa)

- inches of water

- inches of mercury

- kilogram-forces/sq. centimeter

- kilogram-forces/sq. meter

- kilopascals (kPa)

- kips/sq. Inch

- meganewtons/sq. meter

- meters of water

- millibars

- millimeters of mercury

- millimeter of water

- newtons/sq. centimeter

- newtons/sq. meter

- newtons/sq. millimeter

- pascals (Pa)

- pounds-force/sq. foot

- pound-force/sq. inch

- poundals/sq. foot

- tons (UK)-force/sq. foot

- tons (UK)-force/sq. inch

- tons (US)-force/sq. foot

- tons (US)-force/sq. foot

- tonnes-force/sq. cm

- tonnes-force/sq. meter

- torr (mm Hg 0°C)