Coating Thickness Gauge

Essential for quality control, inspection, and maintenance, ensuring coatings meet specified standards for performance and durability.

Filter by Category

Ex-stock Products

Recent News & Events

ProPak Philippines 2025

February 12-15, 2025

Measurement Technologies Corporation at ProPak Philippines 2025 – Metro Manila, Philippines

Car Coating Thickness Measurement

In car painting and refinishing, measuring paint thickness accurately is essential to achieving a flawless finish and ensuring long-lasting protection. A paint thickness gauge helps you control every layer—from primer to clear coat—ensuring uniform application and preventing costly mistakes.

What is an Automotive Paint Meter? Your Guide to Vehicle Coating Thickness Measurement

A coating thickness gauge is an essential tool for the automotive industry. Often called an automotive paint meter, this handheld sensor is used to accurately measure the thickness of a vehicle’s paint and other coatings without causing any damage. It’s a vital instrument for car dealers, buyers, detailers, and body shops.

This versatile paint measurement tool works on two main principles to determine if a car has been repainted or repaired:

Magnetic Induction: Measures the thickness of non-magnetic coatings, like paint and primer, on ferrous metal parts such as the car’s steel body panels.

Eddy Current: Measures non-conductive coatings, like paint or anodized layers, on non-ferrous metal parts, including aluminum hoods, doors, and fenders.

Using a paint thickness gauge is crucial for several reasons. It helps quickly verify a car’s condition by providing scientific, measurable data. This ensures quality control on the assembly line and helps buyers of used cars spot hidden repairs. An accurate paint thickness measurement can reveal a car’s history, prevent unexpected costs, and help you make a smarter purchasing decision.

Why Paint Thickness Matters in Car Painting

- Guarantees Even Coating: Avoid thin spots or overly thick areas that cause peeling or cracking.

- Prevents Rework: Detect uneven paint or body filler before final drying.

- Ensures Professional Quality: Meet manufacturer specifications and customer expectations.

- Improves Paint Durability: Proper thickness protects the car from rust, weather, and damage.

How the LS239 Paint Thickness Gauge Helps

The LS239 Automotive Paint Thickness Gauge is designed for painters, refinishers, and quality inspectors who demand precision and reliability.

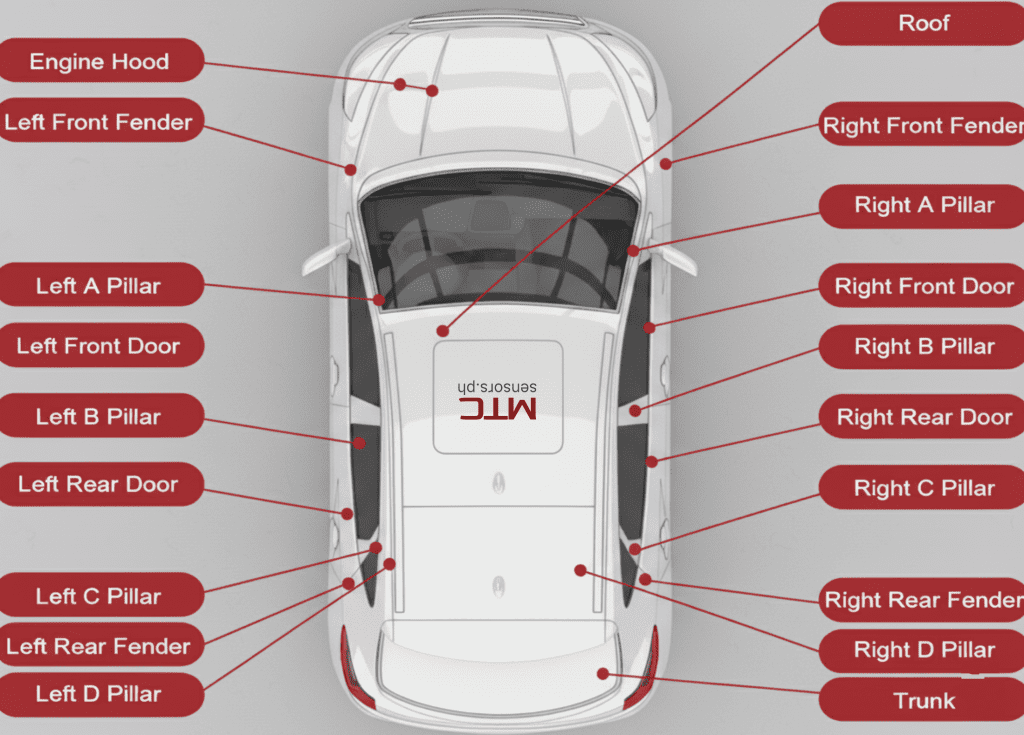

Expert Mode: Measure 19 critical areas of the vehicle for detailed, point-by-point paint thickness checks.

Fast & Accurate: Digital sensor with smart steel, aluminum, and filler detection.

User-Friendly: Intuitive controls, rotating screen, and customizable alarm settings warn you if paint is too thin or thick.

Bluetooth Connectivity: Sync your data instantly to a smartphone app for detailed reporting and record keeping.

Best Practices for Using Paint Thickness Gauges in Painting

Calibrate before every job to ensure accuracy.

Check multiple spots on each panel to confirm uniform paint thickness.

Compare readings against recommended thickness ranges for each paint layer.

Use data to adjust spray techniques and improve finish quality.

The Science Behind the Gauge: How It Works

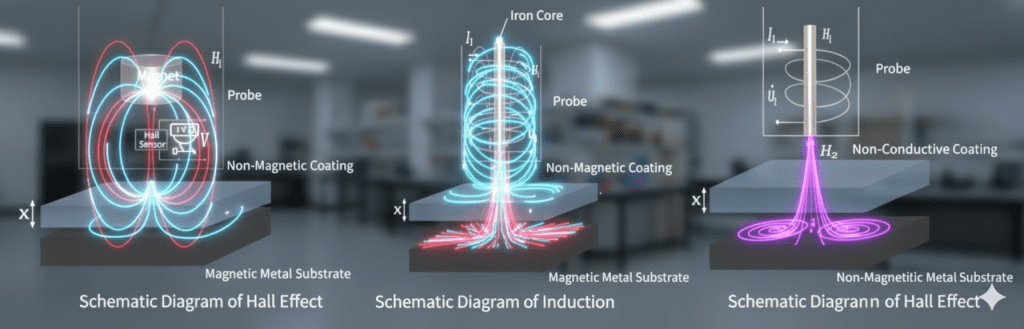

Most digital coating thickness gauges operate on one of two key principles: magnetic induction or eddy current. Some advanced, dual-use thickness gauge combine both for maximum versatility.

1. Magnetic Induction Principle (for Ferrous Metals) This method is used to measure non-magnetic coatings (like paint, plastic, or zinc plating) on magnetic metal substrates such as steel and iron. The gauge’s probe generates a magnetic field. As the probe is placed on the coated surface, the strength of this magnetic field is affected by the distance to the magnetic substrate. The gauge precisely measures this change to determine the coating thickness.

2. Eddy Current Principle (for Non-Ferrous Metals) Ideal for measuring non-conductive coatings (e.g., paint, anodized layers, plastics) on non-magnetic, conductive metal substrates like aluminum, copper, and zinc. The probe creates a high-frequency magnetic field, which induces small electrical currents—known as eddy currents—in the substrate. The strength of these currents changes based on the coating thickness, allowing the gauge to calculate an accurate measurement.

Dual-use devices, such as the Linshang coating thickness tester, automatically detect the substrate type (“Fe” for ferrous, “NFe” for non-ferrous) and switch to the correct measurement principle, simplifying the inspection process.

This Dual Coating Thickness Gauge is a non-destructive testing (NDT) instrument for measuring coating or plating thickness on metal substrates. It uses:

Magnetic induction → for coatings on ferrous metals (e.g., paint on steel)

Eddy current → for coatings on non-ferrous metals (e.g., anodizing on aluminum)

Because it can switch automatically between these two methods, it’s called a dual-use or dual-mode gauge — suitable for almost any metal surface.

Dual-mode measurement (F / NFe)

“F” mode: non-magnetic coatings on a magnetic substrate (e.g., paint on steel).

“NFe” mode: insulating (non-magnetic) coatings on a non-magnetic metallic substrate (e.g., paint/plastic on aluminium, copper, brass, stainless)

Typical Applications by Industry

- Manufacturing & Metal Fabrication – Measuring paint, powder coating, or plating thickness on parts and components.

- Automotive Industry – Used in car inspection and used-car evaluation to detect hidden repairs (variations in paint thickness can reveal bodywork or repainting)

- Construction & Infrastructure – Inspecting steel structures, bridges, pipes, and tanks for paint or corrosion-protective coating thickness

- Aerospace & Marine – Measuring protective coatings on aircraft parts or ship hulls

- Electronics & Electrical – Measuring plating thickness on copper, nickel, or gold coatings used in connectors and circuit boards

- Quality Control & Laboratory Use – In R&D, testing labs, or production quality control lines, it helps validate coating processes

- Inspection & Certification Services – Used by inspection engineers, third-party certifiers, and maintenance teams for regular audit or inspection of coated assets

Examples of Coating–Substrate Combinations

| Coating Type | Substrate | Measurement Method |

|---|---|---|

| Paint, enamel, or lacquer | Steel or iron | Magnetic induction |

| Zinc, chromium, or nickel plating | Steel | Magnetic induction |

| Paint or plastic | Aluminum, copper, brass | Eddy current |

| Anodized layer | Aluminum | Eddy current |

| Insulating coatings | Non-ferrous metals | Eddy current |

MTC supplies a wide selection of coating and material thickness gauges engineered for precision, reliability, and ease of use across multiple industries. Our instruments are designed to provide fast, non-destructive, and highly accurate measurements of coating thickness on both ferrous and non-ferrous substrates. Whether used for quality assurance, production monitoring, or maintenance inspection, these gauges help ensure coatings meet required standards and specifications.

Having trouble selecting the best instrument for your application?

Here’s a guide to help you choose the right instrument for your industry. You may also reach out to our technical team for expert guidance tailored to your specific process needs.