Magnetic Level Float Switch

Supplier of level solutions for tanks and vessels using economical solutions for level detection and alarm in different types of liquid media like diesel, solvents and water based fluids

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

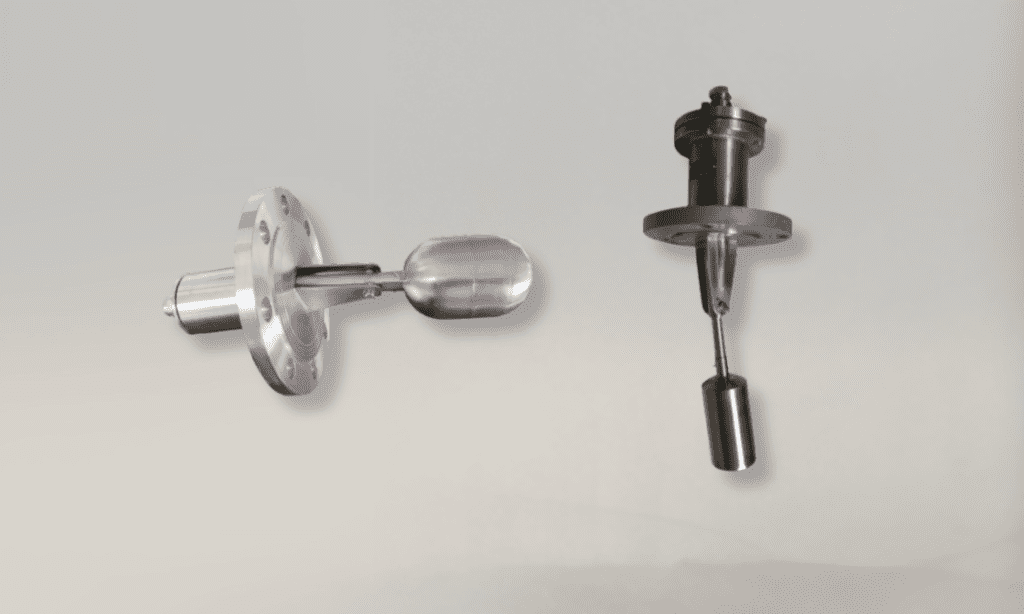

Magnetic Tank Float Level Switch

MTC is a supplier in the Philippines of Magnetic Level Switches. If you are looking to buy a highly reliable switch in PHP/Peso which is cost-effective, then look no further.

The Magnetic Float Switch device is used to detect and control the level of liquids in tanks, vessels, and pipelines. Whether used for pump control, overfill protection, or level alarms, it plays a vital role in many industrial applications throughout the Philippines.

What Is a Magnetic Float Level Switch?

A magnetic level float switch is a type of liquid level sensor that uses a magnet embedded in a float and a reed switch inside a sealed stem to detect the presence or absence of liquid. As the liquid level rises or falls, the float moves accordingly, triggering the reed switch when it reaches a specific point.

This switching action can be used to:

Activate alarms

Control pumps

Open/close valves

Send signals to control panels

How does the Magnetic Float Level Switch Work?

Float – Moves up or down with the liquid level. It is designed to slide along a non-magnetic stem or tube. The float is a hollow component made from buoyant material such as plastic or stainless steel. It contains a small permanent magnet inside.

Reed Switch – A pair of magnetic, flexible metal contacts sealed within a glass tube. When the magnet in the float comes close to the reed switch, the magnetic field causes the reeds to either close (make contact) or open (break contact). This change in state acts as an electrical signal to control or monitor a system.

Switch Activation – As the liquid level rises or falls, the magnet inside the float moves with the liquid. Once the float reaches the switch position, the magnetic field activates the reed switch. The switch state changes from open to closed (or vice versa), sending a signal to connected devices.

Types of Switching Action

Normally Open (NO): The circuit is open until the float rises to the switching point.

Normally Closed (NC): The circuit is closed until the float drops below the switching point.

Some magnetic float switches offer multi-point sensing for high/low level monitoring.

Common Applications

- Water treatment plants

- Oil and chemical tanks

- HVAC systems

- Food and beverage production

- Pumps and reservoirs

- Marine and automotive fuel tanks

Advantages of Magnetic Float Switches

- No power required for basic operation

- Simple design and easy installation

- Highly reliable with minimal moving parts

- Resistant to pressure and temperature extremes

- Low maintenance and cost-effective

Things to Consider When Choosing a Magnetic Float Switch for Level

- Liquid type and compatibility (corrosive, viscous, etc.)

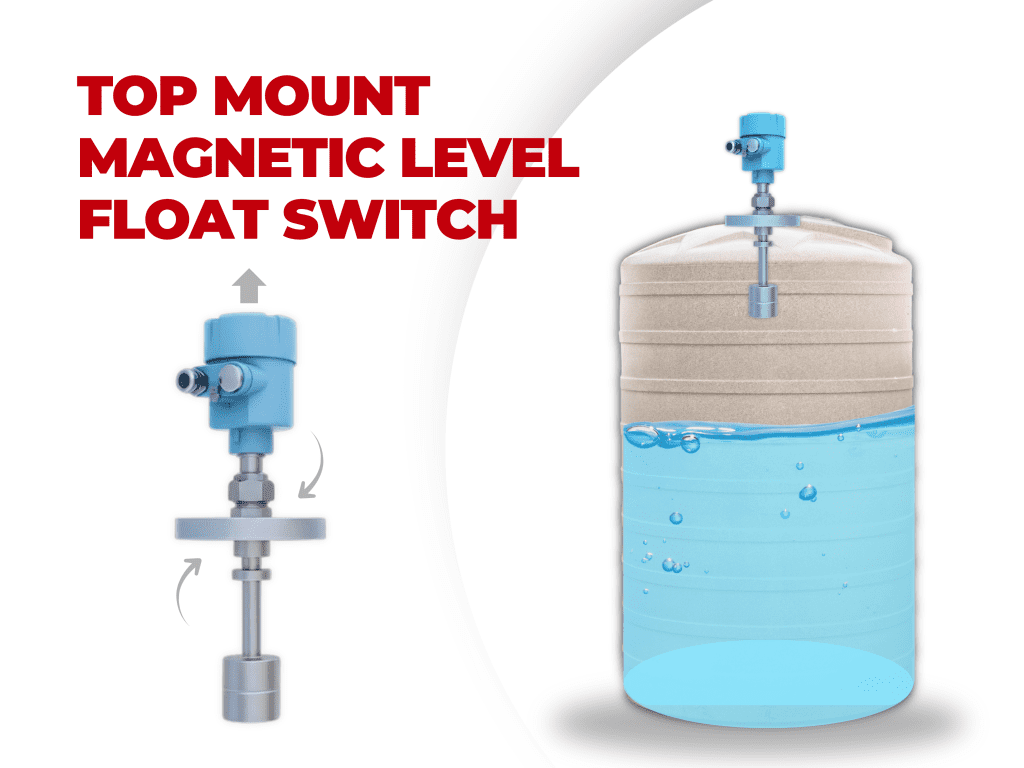

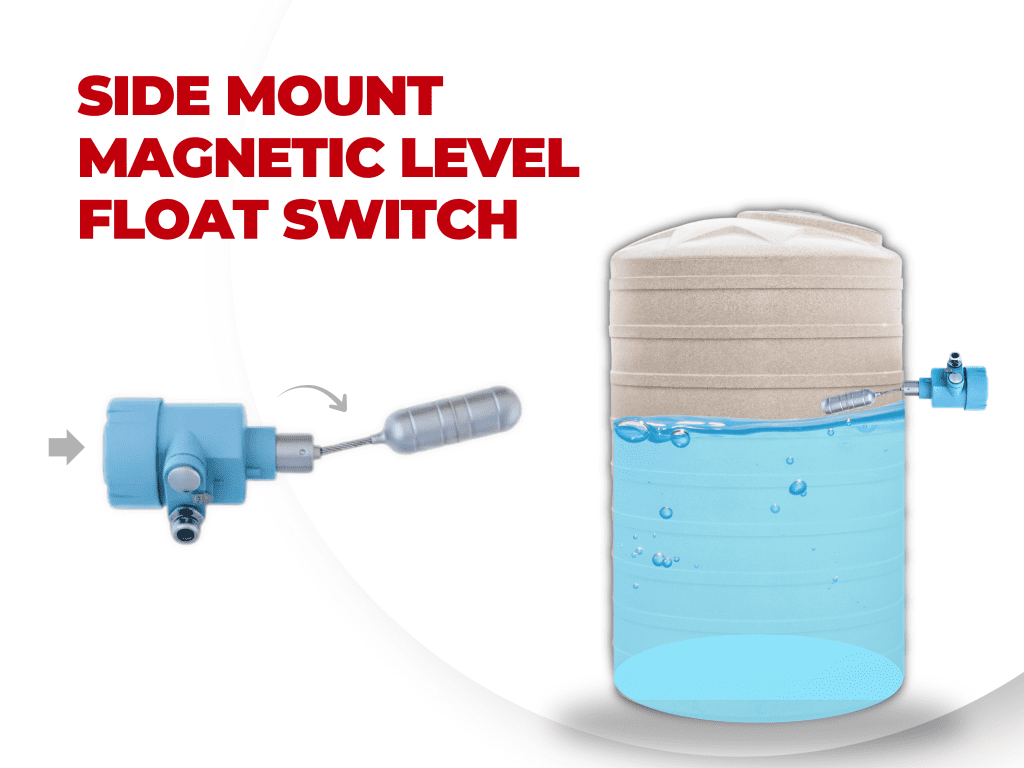

- Mounting style (top-mount, side-mount, vertical)

- Operating temperature and pressure

- Switch rating (voltage/current requirements)

- Material construction (plastic, stainless steel, etc.)

Looking for magnetic float switches?

We supply high-quality float switches for a wide range of applications. Contact us today to find the right model for your system.

Magnetic Level Devices are simple to use and install even in remote locations from industrial plants in Palawan to power plants in Mindanao.

Having trouble selecting the correct pressure instrument for your application?

Here’s a guide to help you choose the right instrument for your industry. You may also reach out to our technical team for expert guidance tailored to your specific process needs.