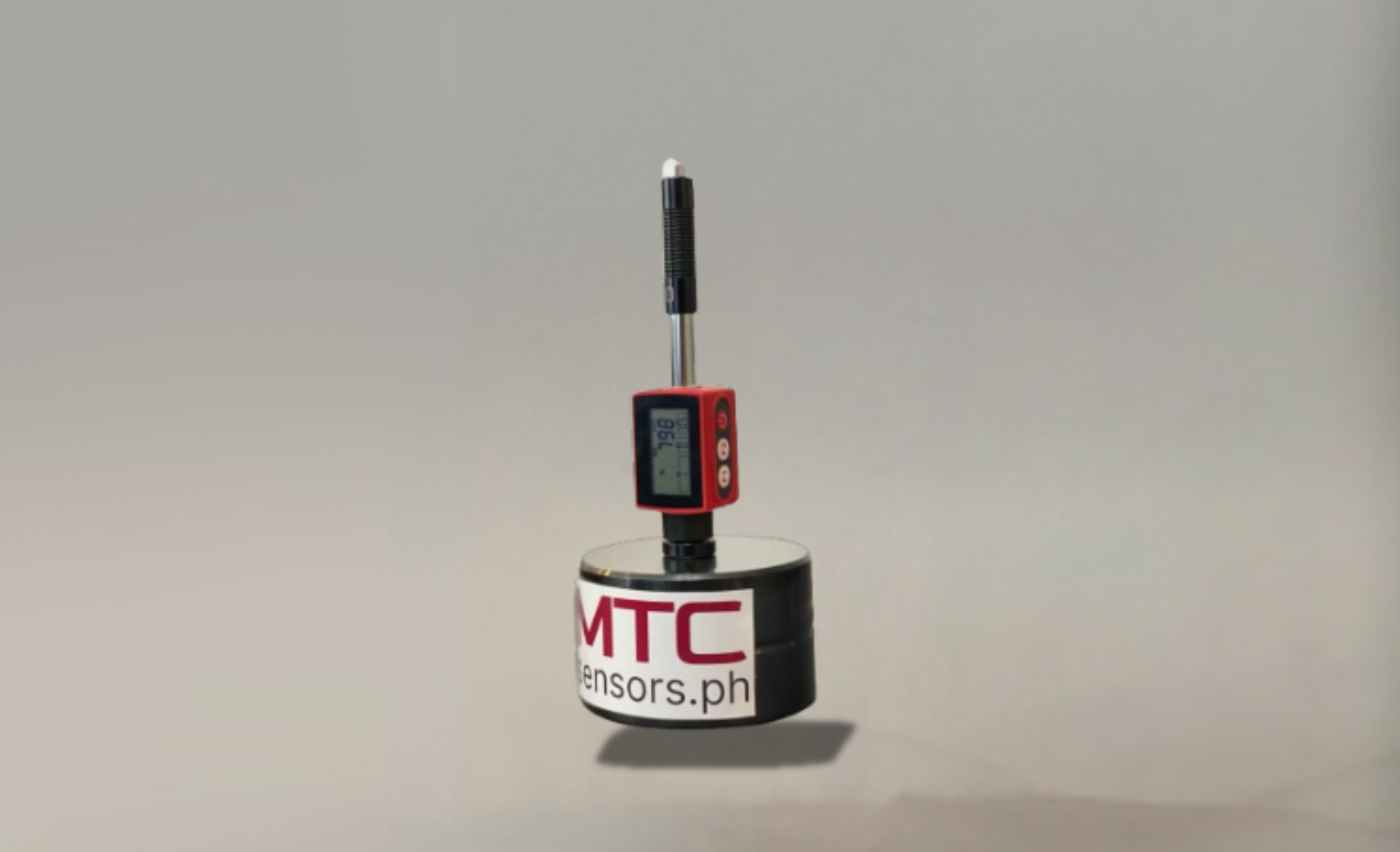

Leeb Hardness Tester

It’s a convenient tool for on-site hardness testing — especially useful for large, fixed, or assembled parts that can’t be easily taken to a laboratory.

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

Understanding the Leeb Hardness Tester

Available Products:

Leeb Hardness Tester

The Leeb Hardness Tester is a portable device designed to measure the hardness of metals and alloys using the rebound principle. Ideal for field inspections and on-site quality control, it provides non-destructive testing for a wide range of metals — including steel, cast iron, aluminum, and copper alloys.

Unlike traditional bench-top hardness testers that require sample cutting or laboratory setups, the Leeb tester offers on-site, non-destructive hardness testing, making it ideal for industrial, manufacturing, and maintenance environments.

Why It’s Called “Leeb Hardness”

Leeb refers to the Leeb rebound hardness testing method, named after its inventor Dieter Leeb, who developed it in the 1970s.

The Leeb principle measures hardness based on the rebound velocity of an impact body striking a metal surface. In simple terms, it determines how “bouncy” the material is — harder materials cause a higher rebound, while softer materials absorb more energy and result in a lower rebound.

The method was standardized as the Leeb Hardness Test (HL) after Dieter Leeb, who introduced this dynamic (rebound-type) testing approach as an alternative to traditional static methods like Rockwell or Vickers.

Principle, Use, and Applications

Using a spring-driven impact device, the tester measures the rebound velocity after striking the test surface to calculate a Leeb hardness value (HL). The device automatically converts results into standard hardness scales such as HRC (Rockwell C), HB (Brinell), HV (Vickers), and HS (Shore) for easy reference.

How It Works

A tungsten carbide ball inside the impact device is projected onto the test surface with a known velocity. The device then measures both the impact velocity (vi) and the rebound velocity (vr) to calculate the Leeb hardness value (HL) using the formula:

HL = 1000×vi/vr

A harder surface results in a higher rebound velocity (and thus a higher HL value), while softer materials absorb more impact energy, resulting in a lower value.

Why Choose a Leeb Hardness Tester?

- Portable, lightweight, and user-friendly design

- Fast, non-destructive hardness testing

- Wide testing range for various metals and alloys

- Automatic conversion to multiple hardness scales

- Optional impact devices for different testing conditions (D, DL, G, C, etc.)

- Digital display with memory storage and data transfer options

Common Applications

- Manufacturing and production lines for quality verification

- Maintenance and inspection of machinery components

- Heat treatment facilities to check hardness consistency

- Power generation and shipbuilding for structural testing

Whether you need advanced data management or simple field testing, MTC offers the MH310 and MH100 Leeb Hardness Testers to meet your specific application needs. Both models deliver accurate, efficient, and portable hardness testing solutions for industrial, automotive, and manufacturing environments.

Other Product:

Having trouble selecting the best instrument for your application?

Here’s a guide to help you choose the right instrument for your industry. You may also reach out to our technical team for expert guidance tailored to your specific process needs.