Fixed Gas Detector

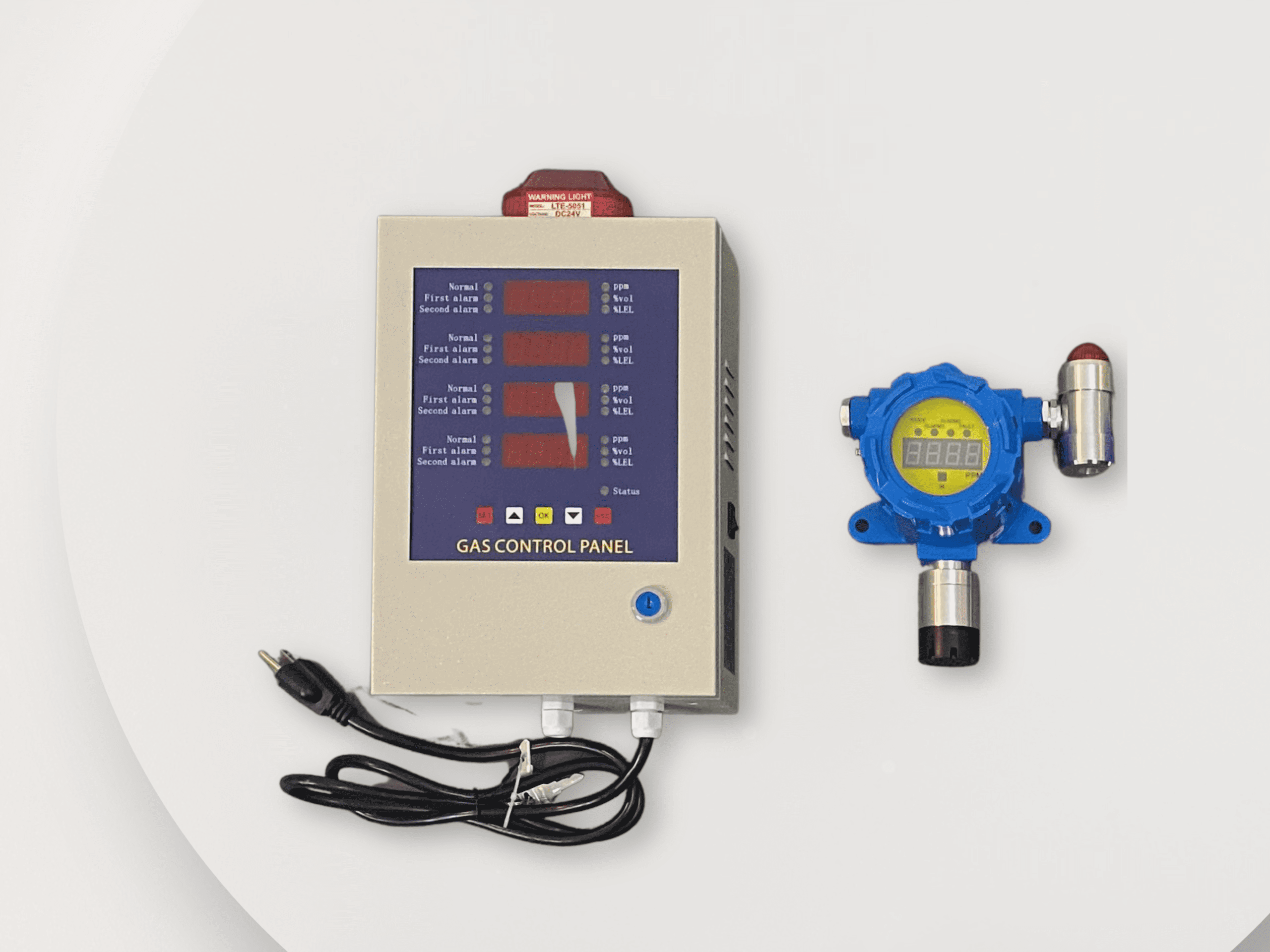

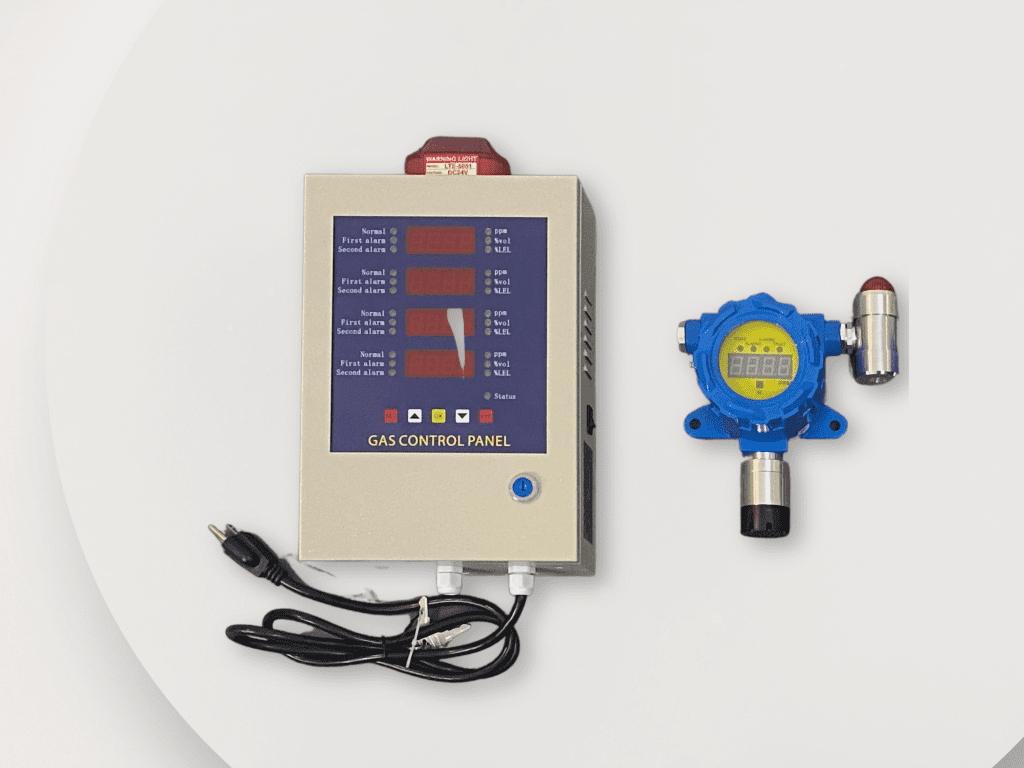

Measurement Technologies Corporation (MTC) supplies reliable and high-performance Fixed Gas Detectors designed for continuous monitoring of hazardous gases in industrial, commercial, and confined environments.

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

Types of Gas Detectors We Supply in the Philippines

Available Products:

What is Gas Detector?

A gas detector is an electronic instrument that continuously monitors the concentration of one or more gases in the air. When the gas concentration reaches a preset limit (alarm threshold), the detector triggers visual and/or audible alarms to alert users of potential danger.

Types of Gas Detectors We Supply:

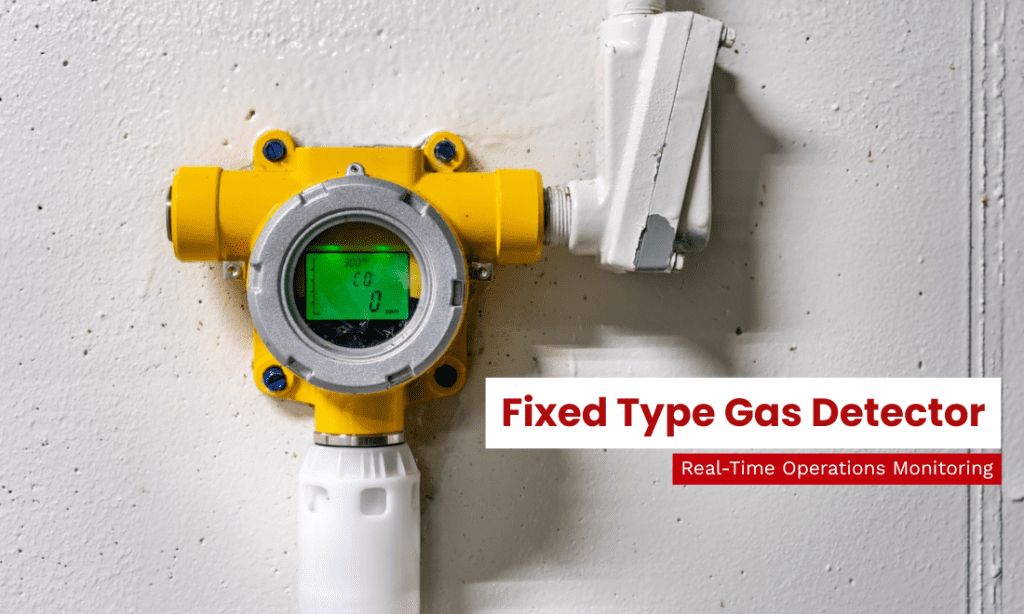

- Fixed Gas Detectors – Installed permanently on walls or ceilings to continuously monitor specific areas such as industrial plants, laboratories, or storage rooms.

- Portable Gas Detectors – Handheld, battery-powered devices used by workers for personal safety in confined or hazardous spaces.

Recommended Gas Detection for your Industry: -> https://sensors.ph/gas-detection-requirements/

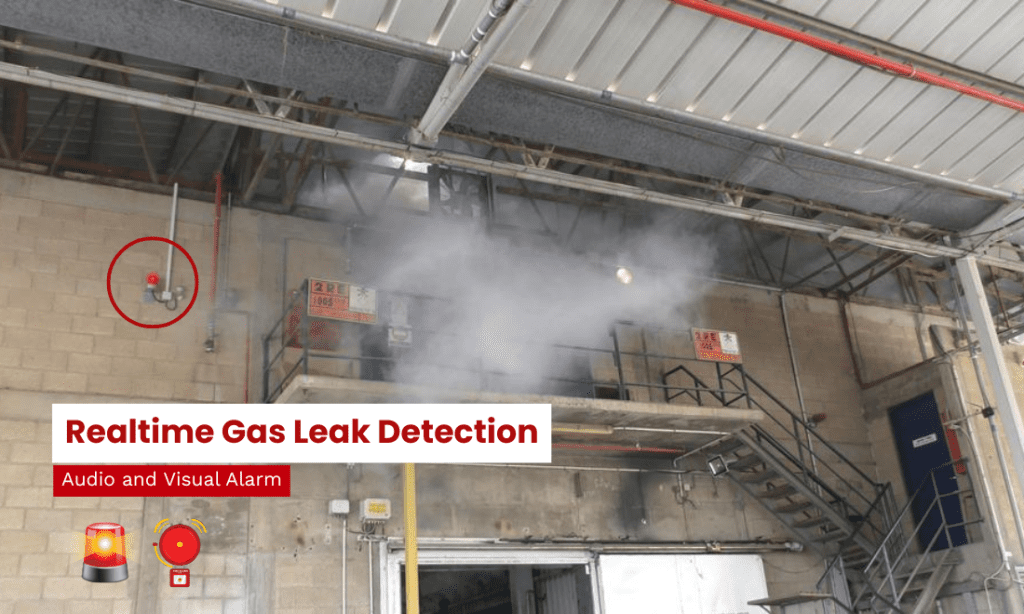

Continuously monitors the air for the presence of combustible, toxic, or oxygen-deficient gases. When gas levels exceed a preset threshold, the detector triggers alarms — such as sirens, flashing lights, or signals to a central control system — to warn operators and activate safety measures.

A fixed gas detector is permanently installed at a specific location to detect hazardous gases such as flammable, toxic, or oxygen-deficient/enriched atmospheres. It continuously measures gas levels and alerts personnel through alarms (visual, audible, or both) when concentrations exceed preset safety limits. These work on similar principles to multi-gas detectors.

Fixed gas detectors are widely used in the Philippines and are becoming even more prevalent as companies place greater emphasis on safety systems. Unlike battery-operated portable detectors, these permanently installed devices continuously monitor specific areas for the presence of toxic or hazardous gases—providing round-the-clock protection and ensuring a safer working environment.

Fixed gas detectors with visual and audio alarms are important for a myriad of industries including storage facilities, refrigeration, mining and of course chemical and food production as well as electronic manufacturing. Below is a short list of detectable gases.

Combustible / Flammable Gases

- Methane (CH₄)

- Propane (C₃H₈)

- Butane (C₄H₁₀)

- Hydrogen (H₂)

- Ethylene (C₂H₄)

- Acetylene (C₂H₂)

- Liquefied Petroleum Gas (LPG)

- Natural Gas (NG)

Toxic Gases

- Carbon Monoxide (CO)

- Hydrogen Sulfide (H₂S)

- Ammonia (NH₃)

- Chlorine (Cl₂)

- Sulfur Dioxide (SO₂)

- Nitrogen Dioxide (NO₂)

- Hydrogen Cyanide (HCN)

- Phosphine (PH₃)

- Ozone (O₃)

Specialty / Industrial Gases

- Refrigerants (R-22, R-32, R-134a, R-404A, R-410A, etc.)

- Silane (SiH₄)

- Arsine (AsH₃)

- Chlorine Dioxide (ClO₂)

- Formaldehyde (CH₂O)

Asphyxiant / Oxygen-Related Gases

- Oxygen (O₂)

- Carbon Dioxide (CO₂)

- Nitrogen (N₂)

Frequently Asked Questions

- What type(s) of gas need to be detected? (e.g., methane, carbon monoxide, hydrogen sulfide, ammonia, etc.)

- How many detection points or monitoring locations are required

- Is the installation area indoor or outdoor?

- What are the environmental conditions? (e.g., temperature, humidity, presence of dust or moisture)

- Do you need a single gas detector or a multi-gas detection system?

- Should the detector include audible/visual alarms (buzzer, strobe light)?

- Do you need the detector to connect to a control panel, PLC, or BMS (Building Management System)?

- What is the power source available? (e.g., 220VAC, 24VDC)

- Do you have any certification requirements? (e.g., explosion-proof, ATEX, IECEx)

- Where will the detector be mounted? (e.g., wall-mounted, ceiling-mounted, near floor level)

What is the advantage of Fixed Gas detectors in the Philippines?

24 Hour around the clock Monitoring through sensors and display/alarm panels. Checking for gas leaks and upset situations that might be detrimental to a manufacturing process or the health and safety of personnel. The fixed gas detectors are not only early warning devices but a kind of automation for those who want to have a system in place that does not require personnel to continually visit the area with a portable device.

Please note that Fixed systems are often more cost-effective than portable monitors in large or high-risk facilities.

Fixed Gas Detectors can sense a Variety of Gas Types:

Fixed detectors can monitor a wide range of gases, including oxygen, hydrogen sulfide (H2S), carbon monoxide (CO), methane (CH4), and sulfur dioxide (SO2), Hydrogen (H2), Ammonia (NH3), Oxygen (O2), and Chlorine (Cl2).

A portable gas detector is a highly sensitive handheld instrument designed for rapid and accurate detection of gas concentrations in industrial and commercial environments. It is widely used in gas stations, chemical plants, laboratories, hazardous material storage areas, and petrochemical facilities to ensure personnel safety and prevent equipment damage.

These detectors can simultaneously measure several gases such as oxygen (O₂), carbon monoxide (CO), hydrogen sulfide (H₂S), and combustible gases (LEL or CH₄). By alerting users with audible, visual, and vibration alarms when dangerous concentrations are detected, the device helps prevent exposure, explosions, and oxygen deficiency accidents.

Detected Gases: Poisonous and Harmful Gases

Sampling Method: Natural Diffusion Type

Power Supply Voltage: DC 3.7V 3000mA

Dimensions: L 120mm x W 56mm x H 30mm

Having trouble selecting the best instrument for your application?

Here’s a guide to help you choose the right instrument for your industry. You may also reach out to our technical team for expert guidance tailored to your specific process needs.