Dust Monitoring Solutions

Dust monitoring solutions are essential for industries where airborne particulates pose risks to worker safety, equipment performance, and environmental compliance.

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

Product Collection

Dust Monitoring Solutions

More About Dust Monitoring Solutions

Designed to detect and measure the concentration of dust particles in various industrial processes. These solutions use real-time monitoring technologies to detect and measure dust levels in industrial and outdoor environments, helping companies mitigate health hazards and comply with regulations.

Frequently Ask Questions

- Dust is monitored using real-time sensors and sampling instruments that detect and measure airborne particulate matter (PM). The monitoring process typically involves; (1) Optical & Laser Sensors – Measure dust concentration by detecting light scattering from particles. (2) Gravimetric Samplers – Collect airborne dust on filters for laboratory analysis. (3) Electrostatic Monitors – Use electric charges to track dust accumulation in industrial settings. (4) Continuous Emission Monitoring Systems (CEMS) – Monitor dust emissions in factories and power plants. (5) Handheld Dust Monitors – Portable devices for on-site air quality assessments.

A dust monitoring system is a setup that continuously measures dust levels in the air to ensure workplace safety, regulatory compliance, and environmental protection. It consists of:

🔹 Sensors – Detects particulate matter (PM1, PM2.5, PM10) in the air.

🔹 Data Loggers – Records and stores dust level readings.

🔹 Real-Time Alerts – Sends notifications when dust exceeds safe limits.

🔹 Control Systems – Integrates with dust suppression technologies to automate responses.Industries such as construction, mining, manufacturing, and pharmaceuticals use these systems to prevent dust-related hazards.

- The best dust control method depends on the application, but common techniques include; (1) Wet Suppression – Spraying water or mist to settle airborne dust. (2) Dust Collection Systems – Using industrial dust extractors and baghouse filters to trap dust. (3) Electrostatic Precipitators – Charging dust particles to remove them from air streams. (4) Ventilation & Air Filtration – Installing HEPA filters to capture fine dust in enclosed spaces. (5) Chemical Dust Suppressants – Applying special coatings or binders to reduce dust formation.

Best practice: A combination of monitoring and control technologies ensures effective dust suppression.

Yes, several types of dust sensors can detect and measure airborne particulate matter:

🔹Laser-Based PM Sensors – Uses light scattering to detect PM1, PM2.5, and PM10 levels.

🔹Optical Particle Counters (OPC) – Measures dust concentration in real time.

🔹Infrared Dust Sensors – Detects dust using infrared light absorption.

🔹Gravimetric Sensors – Collects dust for laboratory analysis of composition and weight.

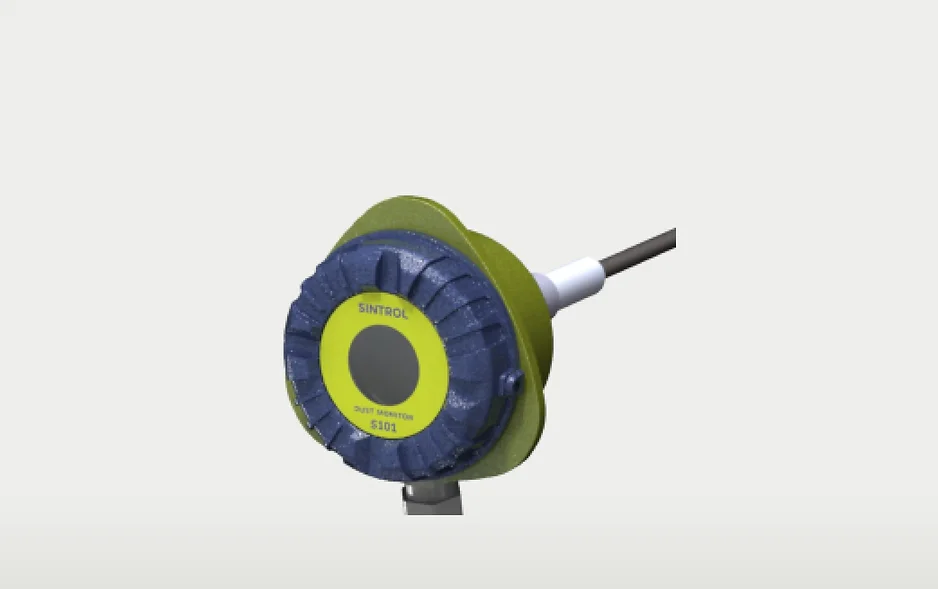

Sintrol dust monitors are designed to reduce filter malfunction discovery time, minimizing maintenance costs and preventing equipment contamination and product loss. By ensuring real-time monitoring of airborne particulates, these devices help industries increase plant availability and operational efficiency.

Need assistance choosing the right Dust Monitoring Solutions? Contact us today for expert recommendations and fast delivery!

Other Products

S303 / 303 Ex Dust Monitor

Overview Features & Benefits Specifications Overview Sintrol S303/S303 Ex is

S201 / S201 Ex Dust Monitor

Overview Features & Benefits Specifications Overview Sintrol S201/S201 Ex is

S203 / S203 Ex Dust Monitor

Overview Features & Benefits Specifications Overview Sintrol S203/S203 Ex is

Exo Dust Monitor for Wet Gases

Overview Features & Benefits Specifications Overview DumoPro is a powerful