Analog Pressure Gauge vs. Digital Pressure Gauge

Pressure measurement is essential across industries—whether you’re monitoring pipelines, hydraulic systems, air compressors, boilers, pumps, or critical process equipment. Choosing the right pressure gauge helps ensure safety, accuracy, and system reliability.

In this guide, we compare analog pressure gauges and digital pressure gauges to help engineers, technicians, and facility managers in the Philippines decide which instrument best fits their application.

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

Which One Should You Use?

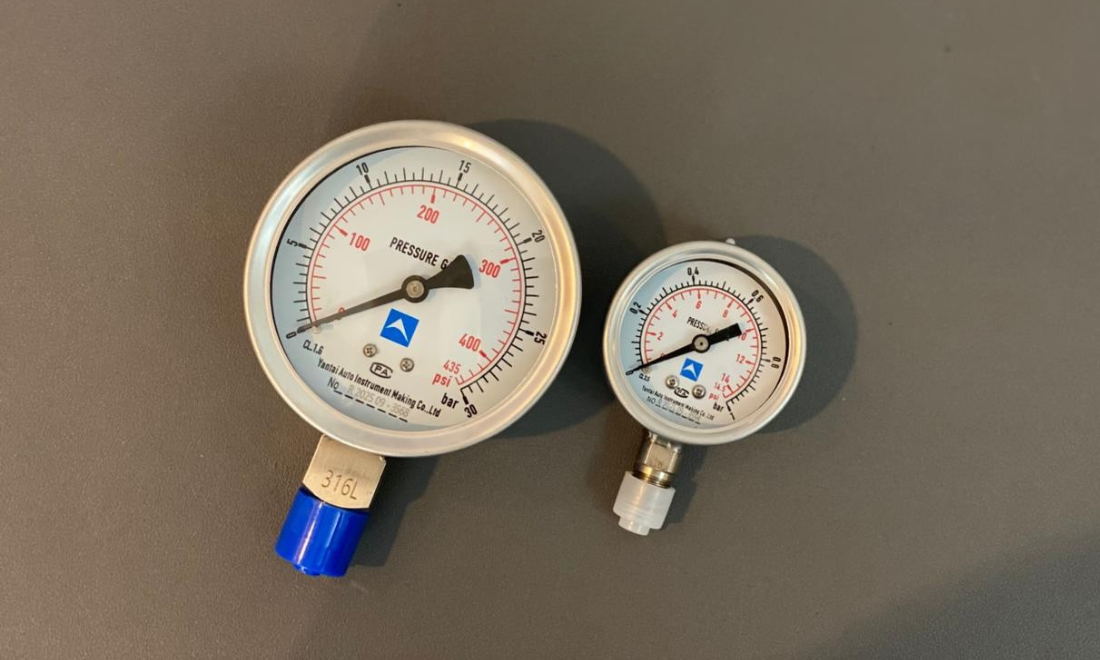

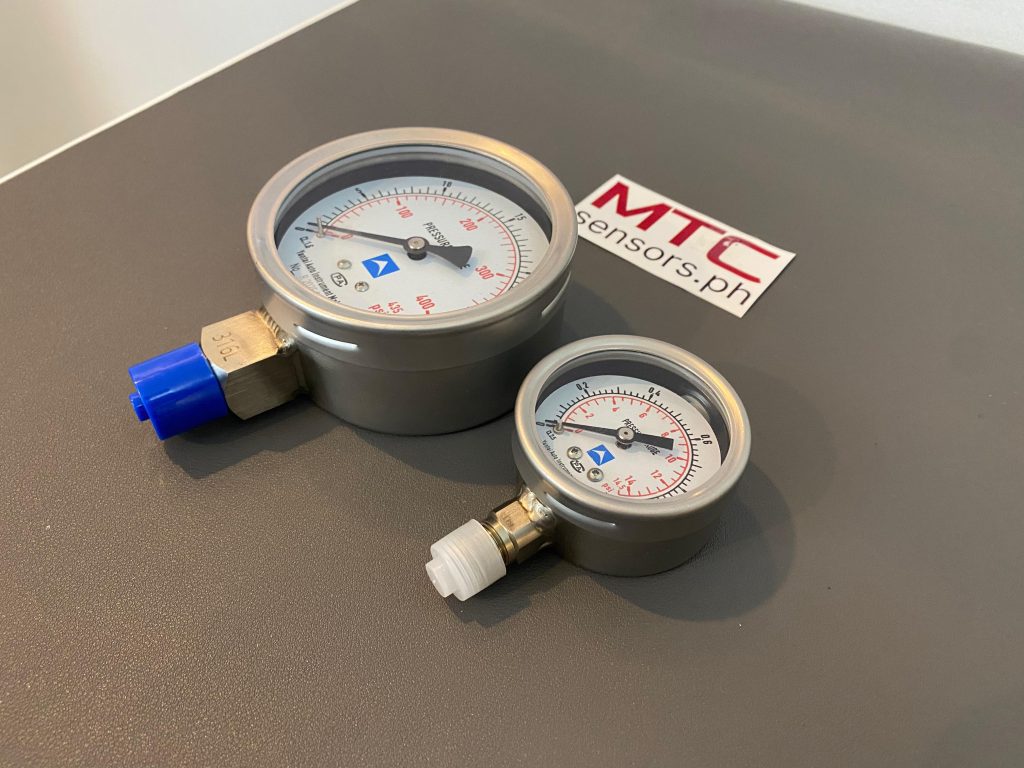

What Is an Analog Pressure Gauge?

An analog pressure gauge, also known as a mechanical pressure gauge, uses a Bourdon tube or similar mechanism to provide a pressure reading through a dial and pointer.

Common Applications

- Air compressors

- Pumps and pipelines

- HVAC systems

- Water treatment plants

- Manufacturing facilities

- Hydraulic systems

Advantage of Analog Gauges

- Cost-Effective – The most affordable option for general industrial use.

- No Power Source Needed – Analog gauges operate mechanically—no batteries or electricity required.

- Durable for Harsh Environments – Ideal for high-pressure systems, vibration-heavy equipment, and rugged conditions.

- Instant Visual Reading – The dial makes it easy to see pressure trends at a glance.

What Is a Digital Pressure Gauge?

A digital pressure gauge uses an electronic pressure sensor and displays measurements on a digital screen.

Common Applications

- Calibration labs

- Quality assurance (QA/QC)

- Research and development

- Pharmaceutical and food processing

- Pressure testing and system diagnostics

- High-precision industrial processes

Advantage of Digital Gauges

- High Accuracy & Precision – Provides more accurate readings than analog gauges. Ideal for critical processes.

- Multiple Units of Measurement – Switch between bar, PSI, MPa, kPa, etc.

- Data Logging & Connectivity (model-dependent) – Some digital gauges can store readings or connect to external systems.

- Easier to Read – The numeric display eliminates the guesswork found in analog dials.

Comparison of Analog and Digital Pressure Gauge

| Feature | Analog Pressure Gauge | Digital Pressure Gauge |

|---|---|---|

| Accuracy | Good for general use | Higher, suitable for precision tasks |

| Power Requirement | No power needed | Requires battery or power |

| Durability | Very durable, shock-resistant | Sensitive to moisture & rough handling |

| Readability | Dial may be harder to read | Clear, digital display |

| Cost | More affordable | More expensive |

| Best Use | Everyday monitoring | Critical measurement & diagnostics |

Which Gauge Should You Choose?

Choose an Analog Pressure Gauge if you need:

- A low-cost, reliable pressure indicator

- A gauge that works without power

- A durable instrument for rugged environments

- Basic monitoring of pumps, compressors, and pipelines

Choose a Digital Pressure Gauge if you need:

- High accuracy for sensitive processes

- Data logging or advanced features

- Easy-to-read pressure values

- Measurement flexibility (multiple units, fast sampling)

Why Selecting the Right Gauge Matters

Using the wrong type of gauge can lead to:

- Incorrect pressure readings

- Equipment damage

- Wasted energy

- Unsafe operating conditions

- Failed compliance inspections

With the right gauge, you ensure:

- Accurate measurement

- Process safety

- Efficient system performance

- Better decision-making

Looking for Reliable Pressure Gauges in the Philippines?

At MTC, we supply a wide range of analog and digital pressure gauges suitable for:

- Industrial machinery

- Oil & gas

- Food & beverage

- HVAC

- Water and wastewater

- Manufacturing

- Laboratory applications

Whether you need a rugged mechanical gauge or a precision digital instrument — we can help you choose the right one. If in doubt, ask!

Here’s a guide to help you choose the right instrument for your industry. You may also reach out to our technical team for expert guidance tailored to your specific process needs.