Maintenance & Condition Monitoring

Vibration Meters | Vibration Sensors | Vibration Probes | Electric Motor Checkers | Pump and Motor Vibration Test Equipment

Filter by Category

Ex-stock Products

Recent News & Events

Measurement Technologies Corporation to exhibit at ProPak Philippines 2026 - Metro Manila, Philippines

October 24, 2025

We look forward to seeing you again at Propak 2026 where we hope to showcase some of our new products!

Vibration Logger Sensors

Vibration Meter for Motors

This product is a great analysis and warning tool for mechanical engineers dealing with rotating equipment such as motors, pumps and gears. The device is compact but with multi-sensing capabilities which enable operators to know whether or not motors, pumps and gears are working optimally by using an approach which monitors the important parameters that occur due to vibration.

Monitor Vibration Effortlessly

Since vibration can be detected in 3 modes (horizontal, vertical and axial) it is possible to quickly diagnose issues such as undesirable alignments & improper installation & provide the sensed data needed to promptly diagnose and remedy for good maintenance to avoid unnecessary further damage & decreased lifespan

- Detects machine health across all axes with a broad, responsive vibration frequency window.

- Lets you adjust how often data is collected based on your machine’s behaviour.

- Performs flawlessly in harsh conditions—from freezing warehouses to high-temperature factory zones.

- No cables, no proximity issues—connects seamlessly over long distances with Bluetooth 5.2.

- Mounts in seconds using either a strong magnetic base or secure M8 threading.

- Syncs effortlessly with your Android device so insights are always in your pocket.

Intelligent and Compact Vibration Monitors. Excellent tool for easier maintenance of motors in the Philippines.

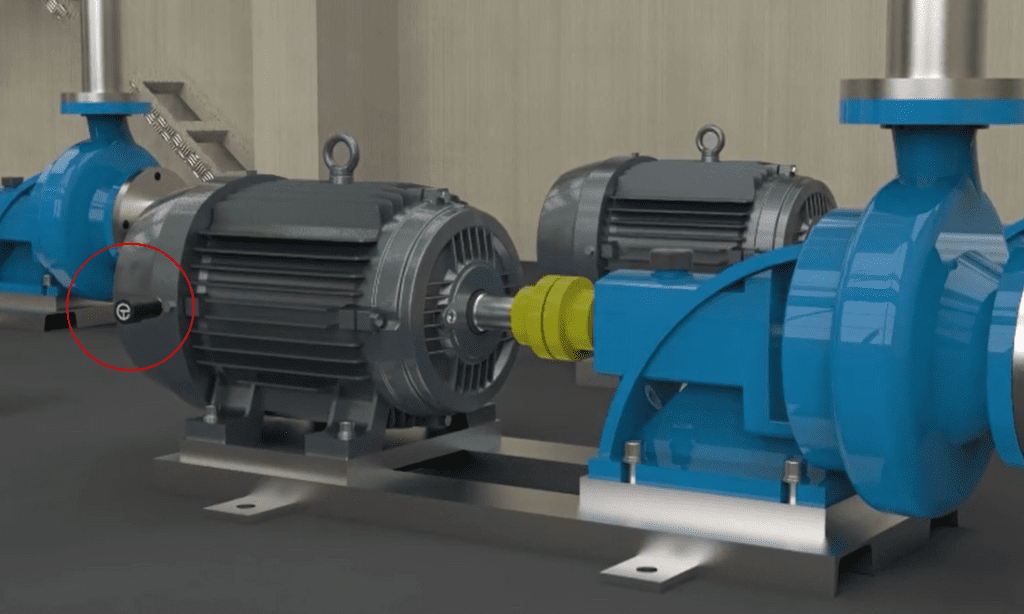

Motor Checker ET 4P

Motor Checker ET 4P can be used to detect electrical fault in the machine, without any need for dismantling the motor.

The motor checker ET 4P is a hand-held diagnostic tool that can be used to detect the condition of an electric motor. The motor checker can also help in checking the quality and condition of motors even before their installation and make the process more efficient.

Motor Checker ET 4P can be used to detect electrical fault in the machine, without any need for dismantling the motor.

The motor checker ET 4P is a hand-held diagnostic tool that can be used to detect the condition of an electric motor. The motor checker can also help in checking the quality and condition of motors even before their installation and make the process more efficient.

The instrument can be operated in different modes to identify various types of faults, including but not limited to:

- Open circuits

- Loose connections

- Short circuits in a winding coil

- Defects in rotor bars and faulty insulation

These faults are identified all without dismounting the machine. The motor checker can also measure insulation resistance to evaluate how effective can the insulation in a machine resist the flow of electric current. In addition, it can enable early detection of inter-turn short circuit, which is a major reason for motor breakdowns. Motor insulation is tested with a high voltage of up to 500 V DC supplied by the instrument.

The simple operation makes it the best supporting aid for electrical engineers in quick and accurate assessment of motor conditions. It is powered by 1.5V X 6AA size cells with electronic zero-set facility. With its in-built low battery indication, the engineers are promptly notified on the need to charge for seamless use.

Having trouble selecting the best instrument for your application?

Here’s a guide to help you choose the right instrument for your industry. You may also reach out to our technical team for expert guidance tailored to your specific process needs.